That grocery run shouldn’t feel like a workout in itself. Without a rear bike rack, you’re stuck with uncomfortable backpacks, unstable handlebar bags, or worse—balancing bags on your handlebars while dodging traffic. Installing a rear bike rack transforms your ordinary bicycle into a practical cargo machine, but improper installation leads to wobbling, tire rubbing, and potential safety hazards. This guide reveals exactly how to install a rear bike rack correctly on any bicycle type, whether you have mounting eyelets or need alternative solutions.

You’ll discover which tools actually matter (hint: your standard Allen key set isn’t enough), how to avoid the most common installation mistakes that cause rack failure, and specific techniques for disc brakes, full suspension bikes, and frames with no mounting points. By the end, you’ll have a rock-solid rack that handles heavy loads without compromising your ride quality.

Verify Your Bike’s Rack Compatibility Before Buying

Don’t waste money on a rack that won’t fit your bike. Your frame’s mounting options determine which rack system works—and skipping this step causes 80% of installation failures. Most modern hybrid, touring, and city bikes have standard eyelets, but many performance road bikes and mountain bikes require specialized mounting solutions.

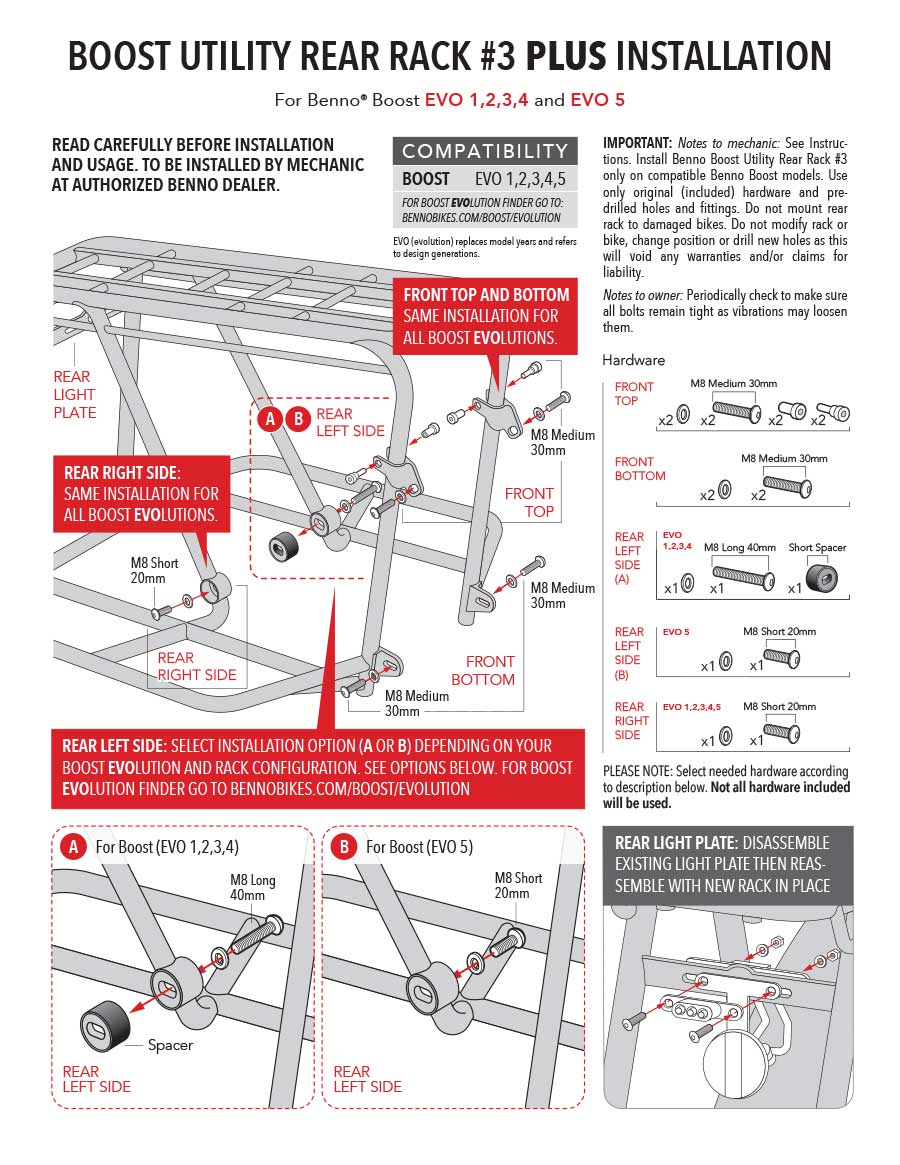

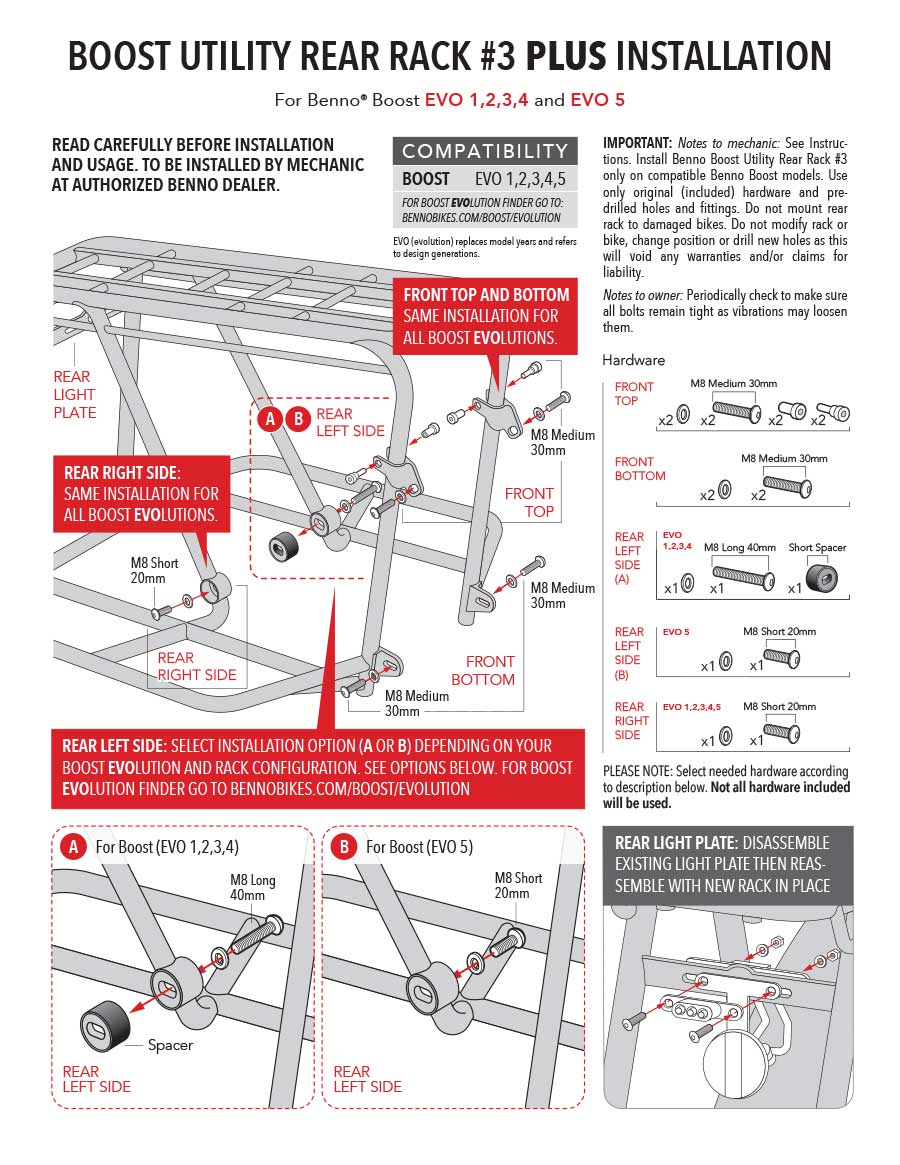

Critical compatibility checks:

– Dropout eyelets: Inspect near your rear axle for small threaded holes (most common mounting point)

– Seat stay eyelets: Look 4-6 inches below your saddle for small threaded inserts on the frame stays

– Brake type: Disc brake systems need specific offset racks to avoid caliper interference

– Wheel clearance: Measure 5mm minimum space between tire and potential rack position

If your bike lacks eyelets, don’t panic—P-clamps can create mounting points on nearly any frame tube. But avoid mounting racks to carbon fiber frames without professional guidance, as improper installation can compromise frame integrity.

Gather These 7 Essential Tools Before Starting

Rushing installation with inadequate tools strips threads and creates dangerous instability. Most DIYers underestimate the specialized hardware needed beyond basic Allen keys.

Non-negotiable tools:

– 4mm, 5mm, and 6mm Allen keys (T-handle versions provide better torque control)

– Torque wrench calibrated for 5-7 Nm range (critical for carbon frames)

– Medium-strength thread locker (Loctite 243 or equivalent)

– Electrical tape for frame protection

– Bike stand or stable work surface

– Digital calipers for precise measurements

– Disc brake spacer (if applicable)

Pro tip: Test-fit your rack with hand-tight bolts before final installation—this reveals alignment issues without risking stripped threads. Budget 45-60 minutes for standard installations, or 90+ minutes for disc brake or eyelet-free setups.

Install Standard Eyelet-Mounted Racks in 5 Critical Steps

Position and Secure Lower Mounting Points

Remove your rear wheel to access dropout eyelets easily. Insert the rack’s lower bolts through the rack legs into the eyelets, hand-tightening just enough to hold position. Crucial check: Ensure the rack legs don’t contact your derailleur cage or chain—many riders overlook this until mid-ride when shifting fails.

Apply electrical tape to frame contact points before tightening. Steel frames tolerate direct metal contact, but aluminum and carbon require protection against galvanic corrosion.

Attach Upper Support Struts Correctly

Cut supplied struts to length using a hacksaw, leaving 1-2mm extra for final adjustment. Mount struts to seat stay eyelets at a 45-degree angle—not vertical—as this triangulation dramatically increases load capacity. Warning: Horizontal struts create dangerous leverage that can snap mounting points under heavy loads.

Tighten upper bolts last—this allows final alignment adjustments. The rack platform must remain perfectly level when viewed from the side, with equal clearance on both sides of the tire.

Achieve Perfect Rack Alignment

Misalignment causes tire rubbing and premature wear. With wheel reinstalled, spin it slowly while checking for:

– Minimum 5mm clearance between tire and rack

– No brake caliper interference during rotation

– Heel clearance when pedaling (critical for panniers)

Adjust strut lengths incrementally—1mm changes make significant differences. For disc brake systems, verify 10mm minimum clearance from rotors to prevent dangerous contact during braking.

Apply Proper Torque and Thread Locker

Tighten all bolts gradually in a crisscross pattern like automotive lug nuts. Use your torque wrench set to 5-7 Nm—never guess. Aluminum frames need the lower end (5 Nm), steel can handle 7 Nm. Apply medium-strength thread locker to all bolts before final tightening to prevent vibration loosening.

Critical mistake to avoid: Over-tightening P-clamps on carbon frames causes catastrophic failure. Never exceed 5 Nm on carbon components.

Conduct Final Safety Verification

Before your first ride, perform these checks:

– Shake the rack vigorously—no movement should occur at mounting points

– Spin the wheel freely—zero rubbing sounds or resistance

– Test brake function with rack installed—no rotor interference

– Check all bolts with torque wrench after 24 hours (vibration loosens hardware)

Fix Disc Brake Installation Challenges in 3 Steps

Disc brakes complicate rack installation because calipers occupy standard mounting space. Standard racks won’t fit—you need a disc-specific model with offset legs that curve around calipers.

Installation sequence:

1. Position rack legs outside the brake caliper area

2. Insert longer bolts through rack into dropout eyelets

3. Add spacer washers between rack and dropout if needed

Verify 10mm minimum clearance from brake rotor to rack leg. Spin the wheel slowly while watching the rotor—if the rack contacts the rotor, you risk catastrophic braking failure. Disc-specific racks often require proprietary mounting hardware, so never substitute standard bolts.

Handle Eyelet-Free Bikes with P-Clamp Mastery

No eyelets? P-clamps create secure mounting points on nearly any frame tube when installed correctly.

Lower clamp positioning:

– Mount on chainstays 1-2 inches forward of dropouts

– Ensure clamps sit perpendicular to ground

– Tighten to 6 Nm with thread locker

– Use rubber strips between clamp and frame

Upper clamp placement:

– Position 3-4 inches below seat cluster

– Maintain exact symmetry on both seat stays

– Leave 10mm clearance from brake components

Warning: Never mount P-clamps on carbon seat stays—micro-fractures develop over time. Seek professional installation for carbon frames.

Troubleshoot These 3 Common Rack Problems Immediately

Tire Rubbing During Rides

Causes: Improper alignment, bent rack legs, or wheel truing issues

Fix: Loosen upper strut bolts and adjust rack position laterally. If rubbing persists, check wheel trueness—many “rack alignment” issues actually stem from wobbly wheels. For chronic problems, consider shorter cranks to eliminate heel strike with panniers.

Rack Wobble Under Load

Causes: Loose bolts, inadequate strut support, or incorrect mounting angles

Fix: Tighten all bolts to proper torque, add secondary support struts, and verify struts maintain 45-degree angle. Steel racks can be carefully straightened if bent, but replace aluminum racks showing flex.

Stripped Mounting Threads

Causes: Over-tightening, improper bolt sizing, or corrosion

Fix: Install helical thread inserts for permanent repair, or use longer bolts with washers for temporary solution. Never force bolts into damaged threads—this worsens the problem.

Essential Post-Installation Safety Routine

Your rack isn’t “installed” until you complete these critical checks:

Pre-ride inspection:

– Verify all bolts at proper torque

– Confirm minimum 5mm tire clearance

– Test brake operation with loaded rack

– Shake rack to check for movement

Monthly maintenance:

– Remove rack to clean mounting points

– Reapply grease to bolt threads

– Inspect for cracks or metal fatigue

– Replace any worn hardware immediately

Warning: Never exceed your rack’s weight limit—most standard racks support 20-25kg (44-55 lbs). Heavy loads accelerate hardware failure and compromise handling.

When to Call a Professional Bike Mechanic

Some installations demand expert skills. Seek professional help for:

– Carbon fiber frame installations (risk of frame damage)

– Loads exceeding 25kg (requires specialized mounting)

– Custom bracket fabrication needs

– Frame warranty concerns

Standard installations cost $20-50 at most bike shops, while complex setups run $50-100. This small investment prevents costly frame repairs from improper installation.

A properly installed rear bike rack should feel like a seamless extension of your bicycle—not a rattling afterthought. Take time with alignment and torque specifications; rushing leads to dangerous failures. With these precise techniques, you’ll transform your bike into a reliable cargo carrier that handles heavy loads without compromise. Your next errand run will finally feel effortless.