You’re pushing your dirt bike through the whoops, but it just doesn’t have that explosive power you need to clear the next jump. Your riding buddies mention port and polish work as the solution, but what exactly does this mysterious modification do? And more importantly, will it actually help your riding style? Understanding the real impact of dirt bike port and polish work before handing over your cylinder head could save you hundreds of dollars and prevent you from ending up with a bike that’s harder to ride than stock.

Porting and polishing reshapes and smooths your dirt bike’s internal airflow passages to improve engine breathing. While the concept seems simple—better airflow equals more power—the reality involves complex trade-offs that dramatically affect where in the RPM range your power arrives. This isn’t a simple bolt-on upgrade; it’s an engine modification that changes fundamental power delivery characteristics. The difference between a well-executed port job and a botched attempt can mean the difference between winning races and struggling through technical sections.

In this guide, you’ll discover exactly how port and polish work affects two-stroke and four-stroke engines differently, realistic performance gains you can expect, professional pricing breakdowns, and whether this modification makes sense for your specific riding needs. Most importantly, you’ll learn the critical mistakes that turn this performance upgrade into a costly disappointment.

How Porting and Polishing Actually Transforms Engine Performance

Why Smoother Airflow Creates More Power

When you port and polish your dirt bike’s cylinder head, you’re fundamentally changing how air and fuel move through the engine. Porting reshapes the intake and exhaust passages to reduce restrictions, while polishing creates a smoother surface that minimizes turbulence. This combination allows the engine to breathe more efficiently, filling the combustion chamber more completely with each cycle.

The key insight many riders miss is that porting doesn’t just add power—it redistributes where that power occurs in the RPM range. Opening the bottom of the exhaust port increases top-end power, while modifying the top portion boosts low-end torque. A skilled technician can tune these modifications to match your specific riding terrain, whether you need explosive power for motocross jumps or strong low-end grunt for tight trails.

Critical Differences Between Porting and Polishing

Many riders mistakenly treat porting and polishing as a single procedure, but they serve distinct purposes that you should understand before committing to the work:

- Porting involves strategically removing metal to reshape passages, change port timing, and optimize flow characteristics

- Polishing focuses on smoothing surfaces to reduce airflow resistance without altering geometry

You can actually perform these procedures separately depending on your goals. If your stock port shape works well but casting imperfections create turbulence, polishing alone might provide noticeable improvements. Conversely, if your power band needs shifting but surfaces are already smooth, porting without extensive polishing could be the right approach.

Why Intake Port Texture Matters for Two-Stroke Engines

One surprising fact that contradicts common DIY advice: completely mirror-polishing your two-stroke intake ports can actually hurt performance. The slight texture from manufacturing grinding marks helps atomize the fuel charge by creating beneficial turbulence. Over-polishing these surfaces reduces this turbulence, leading to poorer fuel mixing and incomplete combustion.

When performing two-stroke port work, focus polishing efforts on the exhaust port and transfer ports while maintaining some texture on intake surfaces. This balanced approach preserves proper fuel atomization while still improving overall flow efficiency where it matters most for power delivery.

Two-Stroke vs Four-Stroke Porting: Different Engines, Different Approaches

Two-Stroke Porting: Where to Focus Your Modifications

Two-stroke dirt bike porting requires a fundamentally different approach than four-strokes because the intake system works completely differently. With two-strokes, your intake ports are located on the cylinder wall where the reed valve assembly mounts—not in the cylinder head itself. This means cylinder head work focuses almost exclusively on the exhaust port.

For maximum performance gains on two-strokes:

– Prioritize exhaust port modifications to optimize power band location

– Smooth transfer ports but avoid over-polishing intake surfaces

– Consider matching and polishing crankcase passages for additional gains

– Never remove material from the piston ring path areas

Four-Stroke Porting: Valve Jobs and Head Decking Essentials

Four-stroke porting involves reshaping passages in the cylinder head around the intake and exhaust valves. This work almost always includes complementary valve work since the ports and valves must work together for optimal flow.

Professional four-stroke porting typically includes:

– Multi-angle valve seat cutting (4+ angles for optimal sealing and flow)

– Precision port reshaping to match valve size and lift characteristics

– Head decking to increase compression ratio (requires higher-octane fuel)

– Matching intake and exhaust manifolds to port openings

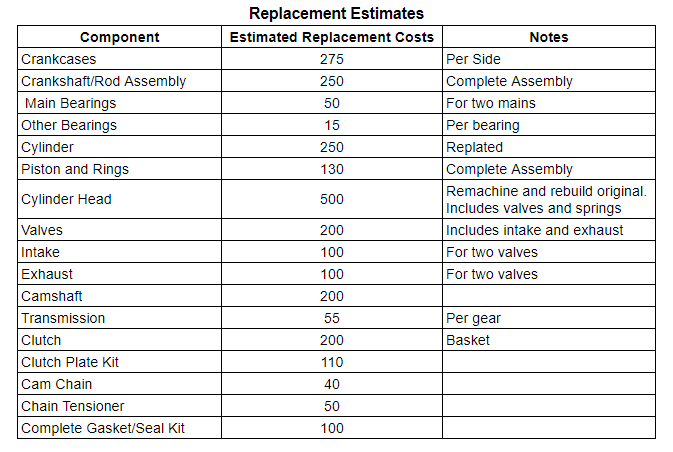

Professional Porting Costs: What You’ll Actually Pay

Standard Pricing for Single and Multi-Cylinder Engines

Understanding the real cost of professional porting prevents sticker shock when you get the bill. Specialty shops typically charge $75 per hour, but most offer flat-rate pricing for common services:

- Single cylinder engines: $275 (includes vapor blast cleaning)

- Twin cylinder engines: $395

- Triple/four-cylinder engines: $575

These prices assume basic porting and polishing without additional services. Always confirm whether the quote includes vapor blasting, which cleans internal passages without damaging critical dimensions—a valuable service often overlooked in DIY attempts.

When CNC Porting Justifies the Higher Cost

CNC porting costs significantly more ($622 starting price) but delivers precision that hand porting can’t match. This technology shines when you need:

– Exact replication across multiple engines (for team racing)

– Complex port shapes that would be difficult to hand-port consistently

– Data-driven optimization based on flow bench testing

For casual riders, hand porting by an experienced technician often provides the best value. But if you’re competing at the highest levels where hundredths of a second matter, CNC porting’s consistency and precision may justify the investment.

DIY Porting: Critical Mistakes to Avoid

Why Most DIY Attempts Damage Performance

Attempting DIY porting without proper knowledge often creates more problems than it solves. The most common mistakes include:

– Over-polishing intake ports on two-stroke engines, reducing fuel atomization

– Removing material from critical wear surfaces without replating

– Creating uneven port shapes that disrupt airflow instead of improving it

– Altering port timing in ways that make the power band unusable

If you attempt even minor port work, focus only on removing casting flash and smoothing sharp edges—not reshaping ports. Use fine-grit sanding rolls instead of aggressive carbide cutters, and never remove material from areas where the piston rings travel.

The Mandatory Replating Step Most DIYers Forget

Professional porting shops always recommend replating cylinders after significant port work, but most DIYers skip this critical step. Nickel carbide or similar plating protects cylinder walls from wear. When you remove material during porting, you compromise this protective layer.

Skipping replating leads to:

– Accelerated cylinder wear

– Premature ring failure

– Potential engine seizure

– Voided warranties on new cylinders

The cost of replating ($200-$400) often exceeds what you’d pay for professional porting in the first place, making DIY a false economy for anything beyond minor cleanup.

Will Porting Require Premium Fuel?

Determining Your Fuel Requirements After Porting

The need for higher-octane fuel depends entirely on how much material was removed during porting:

- Basic polishing without head work: Keep using pump gas (91 octane)

- Moderate porting with minimal head cutting: May require 93 octane

- Aggressive porting with head decking: Likely needs race fuel (100+ octane)

Before committing to porting, discuss your fuel availability with the technician. If you ride in remote areas where premium fuel is scarce, you might need to scale back the modification to maintain pump-gas compatibility.

Is Porting Worth It for Your Riding Style?

When Porting Makes Sense for Recreational Riders

For most trail riders, porting provides minimal benefits that don’t justify the cost and trade-offs. However, specific scenarios where porting could benefit recreational riders include:

– Riding primarily on wide-open trails where top-end power matters most

– Using your bike for occasional competitive events

– Having an older model where stock power has diminished over time

Even in these cases, consider skill development through riding schools before modifying your engine—improved technique often yields greater performance gains than hardware modifications for non-competitive riders.

The Real Performance Gains You Can Expect

Manage your expectations by understanding realistic power increases from professional porting:

– Two-stroke engines: 3-8% peak power increase, often with shifted power band

– Four-stroke engines: 2-5% peak power increase with improved throttle response

– Both types: Noticeable improvement in power delivery smoothness when done correctly

The most significant benefit isn’t necessarily more horsepower—it’s the ability to tailor your power band to match your riding style and terrain. A properly executed port job creates power where you need it most, whether that’s explosive low-end torque for tight trails or screaming top-end for wide-open motocross tracks.

Before you hand over your cylinder, have a detailed conversation with your porting specialist about exactly what you want to achieve. Explain your typical riding conditions, terrain, and goals—whether you need smoother power for technical trails or maximum top-end for racing. A skilled technician can tune the port work to match your specific needs rather than applying a generic “race” setup that might make your bike harder to ride. Remember that porting is just one piece of the performance puzzle; proper jetting, suspension setup, and rider skill often make bigger differences in real-world riding than cylinder work alone.