Few things frustrate dirt bike riders more than hitting the throttle only to feel the engine stutter, sputter, and die instead of accelerating. When your dirt bike bogs down when given gas, you’re dealing with a fuel delivery problem that prevents the engine from getting the power it needs during acceleration. This issue can turn a trail ride into a walking workout, but the good news is that bogging almost always stems from manageable fuel system issues rather than serious engine mechanical failures. Understanding why your bike bogs during acceleration—and knowing how to systematically diagnose and fix the problem—will get you back on the trails with crisp, responsive throttle performance.

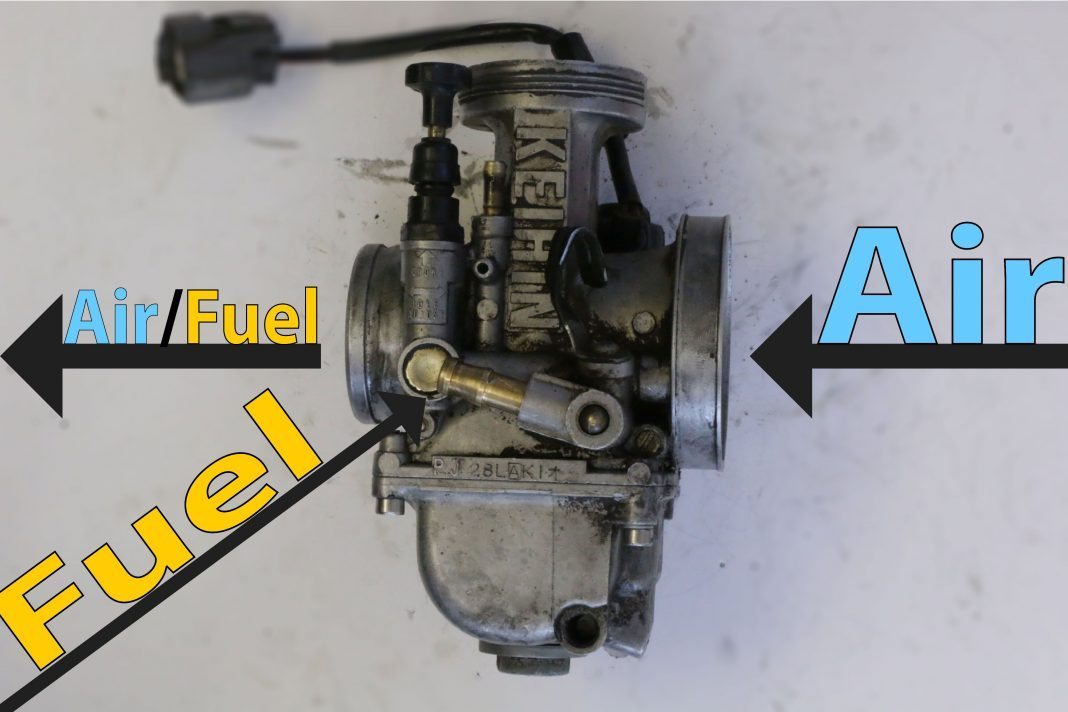

The bogging phenomenon occurs in two distinct forms that require opposite solutions. A lean bog happens when there’s too much air and not enough fuel reaching the combustion chamber. You’ll recognize this by a sputtering engine that sounds like it’s struggling or drowning, often accompanied by loud popping from the exhaust when you let off the throttle. A rich bog develops when excess fuel floods the combustion chamber, creating a sluggish, heavy throttle response that feels like you’re trying to accelerate through molasses. Identifying which type of bog you’re experiencing is the critical first step toward an effective repair.

This guide walks you through every major cause of dirt bike bogging, from simple checks you can perform in minutes to more involved carburetor repairs. Whether your bike only bogs in cold weather or suffers from constant acceleration hesitation, you’ll find the diagnostic steps and solutions needed to restore performance.

Decode Bogging Behavior

Understanding exactly what’s happening inside your engine when bogging occurs gives you the foundation to diagnose and fix the problem effectively. The engine bogs because it cannot deliver adequate fuel to support combustion under load, creating that distinctive hesitation or stalling when you crack the throttle open.

Lean vs Rich Bog Explained

The two bog conditions produce distinctly different symptoms that point you toward opposite remedies. Lean bog occurs when excessive air relative to fuel enters the combustion chamber. The engine sounds like it’s gasping or dying rather than pulling, and you’ll often hear popping or backfiring from the exhaust on deceleration. Checking the spark plug reveals a white, blistered, or corroded electrode—a clear sign the motor is starved of fuel. This condition requires enriching the fuel mixture by increasing jet sizes or adjusting needle position.

Rich bog develops when too much fuel overwhelms the available air. The engine feels sluggish and unresponsive, throttle response becomes heavy and hesitant, and you may notice a strong gasoline smell emanating from the exhaust. The spark plug electrode will appear black and covered in carbon deposits. Rich conditions require leaning out the mixture by reducing jet sizes or lowering the needle position.

Pro Tip: Don’t assume you know which condition you have—always verify with a spark plug inspection before making adjustments. Many riders worsen their bogging by making the wrong jetting changes based on incorrect assumptions.

Common Bogging Scenarios

Bogging doesn’t always occur under every riding condition, and when it manifests provides crucial diagnostic information. Some riders report their bike runs fine at steady throttle but bogs immediately upon acceleration—this pattern points strongly toward accelerator pump issues or pilot circuit problems. Other riders experience bogging only during cold weather riding, which indicates the jetting is too lean for denser cold air conditions. Some bikes bog only after the engine warms up, suggesting an issues with the choke circuit or needle elevation as heat expands internal components.

Note precisely when the bogging occurs and what conditions surround the problem. Does it happen on initial startup, after the bike warms up, only in cold weather, or only during rapid throttle application? These details guide your diagnosis toward the specific system—pilot circuit, accelerator pump, main circuit, or jetting configuration—that needs attention.

Cold Weather Jetting Problems

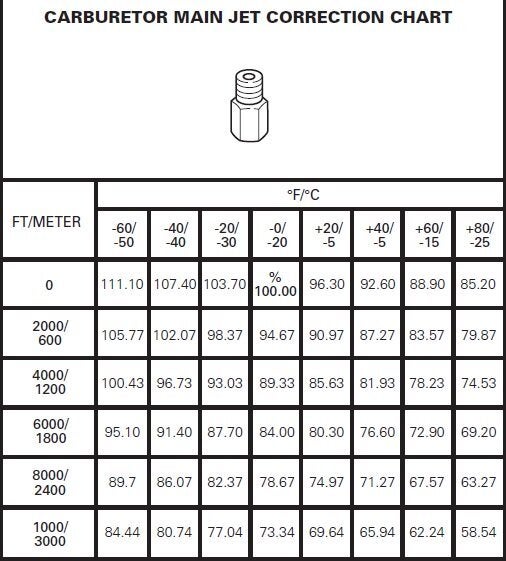

Temperature changes dramatically affect air density, and this seasonal factor explains why many riders experience bogging only during winter months despite their bike running perfectly in summer. Cold air is denser than warm air, meaning each breath contains more oxygen molecules. Your carburetor must deliver additional fuel to match this increased oxygen, and a jetting setup optimized for summer conditions will run dangerously lean when temperatures drop.

Why Colder Air Demands Richer Settings

Many riders intuitively assume that cold air—which feels denser and heavier—would somehow require leaner jetting. This misconception leads to improper seasonal adjustments that worsen bogging. In reality, denser cold air contains more oxygen per volume unit, which means the engine requires more fuel to maintain the optimal air-fuel ratio for combustion. A jetting configuration that works perfectly at 85°F will often run excessively lean at 40°F, producing exactly the bogging behavior riders complain about during winter rides.

The problem typically manifests most dramatically during initial throttle application because this is the moment the carburetor transitions from idle circuits to the main metering system. Any fuel deficiency becomes immediately apparent as the engine struggles to accelerate. Riders whose bikes only bog during cold weather riding while summer operation remains normal should focus their diagnosis on pilot jet sizing, needle position, and accelerator pump condition—components that handle the critical low-to-mid throttle transition where bogging first appears.

Seasonal Jetting Adjustments

Resolving cold-weather bogging typically requires enriching the fuel mixture to account for denser air. This can be accomplished by increasing the pilot jet size (moving up one or two sizes from your summer configuration), raising the needle position by moving the clip to a higher notch, or adjusting the air-fuel mixture screw to allow more fuel entry. Document any changes carefully so they can be reversed when warmer weather returns—running overly rich during summer creates its own set of problems including fouled spark plugs and poor fuel economy.

Inspect Critical Components

Before diving into carburetor disassembly, perform several preliminary inspections that can quickly reveal the bogging cause without requiring extensive work. These checks take only minutes but often identify the problem immediately.

Air Filter Condition Check

A clogged or dirty air filter starves the engine of air while allowing debris to enter the carburetor where it can clog jets and disrupt fuel delivery. Remove the air filter and hold it up to a strong light source. If light doesn’t pass through the filter material easily, the filter needs cleaning or replacement. A dirty filter leads directly to the fuel delivery problems that cause bogging and backfiring. Clean filters with appropriate cleaning solutions and allow them to dry completely before reinstallation. On bikes with oiled foam filters, ensure you apply the correct amount of filter oil—too much oil restricts airflow almost as much as a dirty filter.

Spark Plug Analysis

The spark plug reveals your engine’s overall air-fuel mixture condition at a glance. Remove the plug and examine the electrode and ceramic insulator tip carefully. A black, carbon-covered electrode indicates rich running conditions where too much fuel is entering the combustion chamber. A white, blistered, or corroded electrode signals lean conditions where insufficient fuel is reaching the motor. Either condition can cause bogging during acceleration, and the spark plug’s appearance tells you which direction to adjust your jetting.

Also inspect the spark plug gap and check for proper heat range. An improperly gapped plug or one with the wrong heat range can contribute to running problems that manifest as acceleration hesitation. Ensure the plug is torqued to manufacturer specifications during reinstallation.

Fuel System Inspection

Examine all visible fuel lines, connections, and the fuel filter for cracks, deterioration, or blockages. A restricted fuel line or clogged fuel filter prevents adequate fuel delivery at high throttle openings when the engine demands the most fuel. Check that the fuel petcock is flowing freely and that fuel reaches the carburetor bowl properly. Old or contaminated fuel can clog jets and cause performance problems, so consider draining and replacing the fuel if it has been sitting for extended periods.

Replace Worn Accelerator Pump

The accelerator pump delivers an extra squirt of fuel directly into the carburetor throat whenever you open the throttle quickly. This fuel compensates for the momentary lag in the main circuit’s response, preventing the lean condition that causes bogging during rapid acceleration. When the pump mechanism fails, this protective fuel delivery disappears and bogging occurs immediately upon throttle application.

Symptoms of Pump Failure

A bike that runs perfectly at steady throttle but bogs immediately when you crack the throttle open almost certainly has an accelerator pump problem. The engine may run fine once RPM builds up, but that initial acceleration moment causes the hesitation or stalling. This pattern distinguishes pump failure from jetting problems, which typically affect a broader range of throttle positions.

The pump diaphragm deteriorates over time, developing small holes or tears that cause it to lose pressure and fail to deliver adequate fuel. On many dirt bikes, particularly those based on the WR/YZ platform, diaphragm degradation becomes common after approximately seven years of use. Even if your bike is newer, aggressive riding or extended storage can accelerate diaphragm deterioration.

Pump Replacement Process

Access the accelerator pump by removing the carburetor top cover or dedicated pump cover, depending on your model’s configuration. Locate the diaphragm assembly and note its orientation before removal. Remove the old diaphragm and inspect it for cracks, tears, or degradation. Install the new diaphragm, ensuring it seats properly and that the retaining components are tightened to the correct torque. Some models require priming the pump by manually working the throttle linkage before starting the engine.

After replacement, test the pump operation by observing the spray pattern from the pump nozzle when you quickly open and close the throttle. A healthy pump produces a visible, well-directed fuel spray. Weak or inconsistent spray indicates either persistent diaphragm problems or issues with the pump linkage or check valve.

Complete Diagnostic Checklist

When your dirt bike bogs down when given gas, work through this systematic checklist to identify and resolve the problem efficiently.

Begin with preliminary inspections that take only minutes. Check the air filter condition and ensure it’s clean with proper oil application if required. Inspect the spark plug for signs of mixture condition and verify proper gap. Examine all visible fuel lines and vacuum hoses for cracks, deterioration, or loose connections. Verify fuel quality and ensure you’re using the recommended octane rating.

If preliminary inspections reveal no issues, proceed to carburetor internal inspection. Remove and disassemble the carburetor carefully, documenting component positions. Clean all jets with carburetor cleaner and verify they’re clear. Inspect the accelerator pump diaphragm for damage and replace if worn. Check the float level and adjust if outside specifications. Clean the air-fuel mixture screw and note turn count during removal for proper reinstallation.

Test for vacuum leaks by spraying cleaner around intake connections while the engine runs. Replace any cracked or deteriorating rubber components discovered during this process. If bogging persists after carburetor service, evaluate your jetting configuration for seasonal adjustment, particularly if the problem appeared with temperature changes.

For bikes with persistent bogging despite proper jetting, evaluate accelerator pump operation and consider replacement of the pump diaphragm even if no obvious damage is visible. Consider modifications like airbox changes and jet kits for bikes that resist conventional tuning approaches.

Prevent Future Bogging Issues

Once you’ve resolved your bogging problem, proper maintenance practices prevent the issue from recurring during future rides.

Regular Carburetor Service

Establish a carburetor cleaning schedule based on your riding conditions and fuel quality. Dirt bikes operating in dusty or dirty conditions require more frequent cleaning since more debris enters the air intake. Even with regular air filter maintenance, small particles can pass through and accumulate in jets over time. Many riders find that annual carburetor cleaning during off-season maintenance prevents the gradual jet clogging that eventually causes performance problems.

Use high-quality fuel and consider fuel stabilizers when the bike will sit for extended periods. Stale fuel creates varnish and deposits inside the carburetor that disrupt fuel flow and jet function. If you store your bike for weeks or months at a time, either add stabilizer to fresh fuel or drain the carburetor bowl before storage.

Component Replacement Intervals

Replace rubber intake components and pump diaphragms preventively rather than waiting for failure. These components degrade over time, and failure often occurs during rides far from home. Many riders replace accelerator pump diaphragms as part of regular maintenance every few years or after a specified number of riding hours, regardless of apparent condition. Similarly, inspect intake boots and vacuum hoses during each service and replace any that show signs of age-related deterioration.

Keep detailed records of your maintenance activities, jetting settings, and any performance changes you observe. This documentation helps identify patterns and prevents repeated troubleshooting of the same issues. When changes are made, document them thoroughly so they can be easily reversed if they don’t produce the desired results.

By understanding the fuel delivery system, performing regular maintenance, and addressing problems systematically when they occur, you can eliminate bogging from your riding experience and enjoy the crisp, responsive throttle performance that makes dirt bikes so enjoyable to ride.