Nothing ruins a perfect trail ride faster than a wobbling wheel from improperly tensioned spokes. When just one spoke loosens on your dirt bike—which happens constantly through vibration, jumps, and hard landings—it creates a weak point that compromises the entire wheel assembly. Left unchecked, loose spokes lead to bent rims, damaged hubs, and potentially catastrophic wheel failure that can send you flying mid-ride. Knowing exactly how tight should dirt bike spokes be separates reliable rides from mechanical disasters. This guide delivers the precise tension specifications, testing methods, and maintenance techniques you need to keep your wheels spinning true through every jump and corner. You’ll learn how to spot problem spokes instantly, apply the correct tension, and prevent wheel failures before they happen.

Exact Torque Settings for Dirt Bike Spoke Tightness

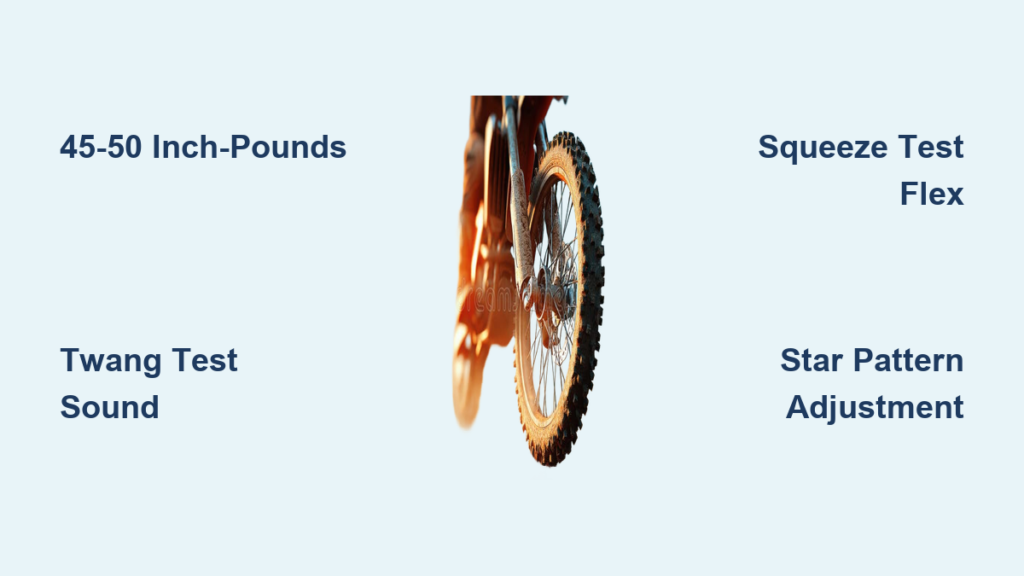

For most dirt bike applications, the proper spoke tension falls between 45-50 inch-pounds of torque, but never rely solely on generic guidelines. Your owner’s manual specifies the exact measurement for your specific model—critical because rim size, spoke count, and riding style dramatically affect the ideal tension. A properly tightened spoke feels “snug” when you squeeze adjacent pairs: firm enough that it doesn’t move freely but not so tight that turning the nipple requires excessive force.

When performing the “twang test” by plucking a spoke like a guitar string, correctly tensioned spokes produce a consistent high-pitched tone across the entire wheel. Loose spokes immediately reveal themselves with a dull thud instead of that crisp sound. Similarly, tapping tensioned spokes with a spoke wrench yields a sharp “ping,” while problem spokes sound muffled and lifeless. This uniform tension across all spokes—not maximum tightness—is what keeps your wheel structurally sound under brutal off-road conditions.

Three Reliable Methods to Check Spoke Tension

Squeeze Test: The No-Tools Inspection Technique

Grab two crossing spokes between your thumb and forefinger and squeeze firmly. Properly tensioned spokes should flex approximately 2-3 millimeters—any more indicates looseness needing immediate attention. Work systematically around the wheel, comparing the feel of each spoke pair against its neighbors. If one pair flexes significantly more than others, you’ve found your problem spoke. This method works best when your hands are clean (grease reduces tactile sensitivity) and requires no tools beyond what nature gave you—making it perfect for pre-ride checks at the trailhead.

Twang Test: Professional Sound-Based Assessment

Run the shaft of a screwdriver across all spokes like a guitar pick while listening carefully to the resulting sounds. Properly tensioned spokes produce a sharp, ringing “twang” that’s consistent across the wheel. Problem spokes stand out immediately with a dull, flat sound. For best results, perform this test in a quiet environment and compare each spoke’s tone to its immediate neighbors. This technique allows you to screen all spokes in under 30 seconds—ideal for race day when time matters. If you hear inconsistent tones, follow up with the squeeze test to confirm which spokes need adjustment.

Torque Wrench Method: Precision Measurement for Critical Adjustments

For absolute accuracy, use a spoke-specific torque wrench set to your bike’s specifications (typically 45-50 inch-pounds). Attach the wrench to each nipple and tighten until it clicks at the set torque. This method eliminates subjectivity but has limitations: corroded or seized spokes produce false readings because friction—not actual tension—triggers the click. Clean spokes and nipples before using this method, as dirt interferes with accurate measurement. For competitive riders or new wheel builds, this precision approach ensures perfect tension consistency across all spokes.

Step-by-Step Spoke Tensioning Procedure

Critical Pre-Adjustment Inspection

Before touching any spokes, spin your wheel and watch for wobble or runout. Check every spoke for visible bends, cracks, or damage—replace any compromised components before proceeding. Place your bike on a center stand for easy wheel rotation, and wipe spokes clean with a dry rag to remove grease that could cause your wrench to slip. Examine each nipple for rounding or damage; damaged nipples often require replacement rather than adjustment.

Star Pattern Adjustment Technique

Start at the spoke immediately following your valve stem (a unique reference point on every wheel). Using a properly fitting spoke wrench, make no more than a quarter-turn clockwise to tighten. After adjusting one spoke, skip the next two and continue this star pattern around the wheel. This prevents localized over-tightening that pulls wheels out of true. When you encounter a significantly loose spoke, resist over-tightening—limit to half-turns and complete the full pattern before returning for additional adjustments.

Wheel Truing Verification Process

After completing your tensioning pass, spin the wheel slowly while watching the rim’s relationship to your brake pads or a stationary pointer. The wheel should rotate smoothly without side-to-side wobble (lateral runout) or up-and-down movement (radial runout). If wobble persists, make targeted adjustments: tighten spokes on the side opposite lateral deviations, and adjust spokes at the low point for radial issues. Always recheck tension across all spokes after truing adjustments.

Must-Have Tools for Perfect Spoke Tension

Your spoke wrench must fit snugly on the nipple—ill-fitting wrenches round off corners, making future adjustments impossible. Invest in a quality wrench with multiple sizes or interchangeable heads that match your specific spoke nipples. For serious maintenance, add a truing stand that isolates wheel issues from frame variables, allowing precise identification of high and low spots. Competitive riders should consider a spoke tension meter that provides quantitative measurements for perfect consistency across all spokes.

Spoke Tension Maintenance Schedule

Pre-Ride Inspection Routine

Check spoke tension before every ride as part of your standard safety check. Professional race teams inspect spokes after every track session—this frequency represents best practice for serious riders. Grab crossing spoke pairs and squeeze to confirm uniform tension. Listen for inconsistent “twang” sounds when plucking spokes. This 60-second check prevents most wheel failures before they happen.

New Wheel Break-In Protocol

Brand new wheels require special attention during their first 10-15 rides. New components settle and seat during this period, causing spokes to loosen significantly more than established wheels. After each initial ride, perform a full tension check and adjustment. Continue this daily routine until spokes maintain tension through two consecutive rides, then transition to standard pre-ride checks.

Warning Signs of Spoke Trouble

Immediate Red Flags Requiring Action

Your wheel developing visible wobble, unusual flex when braking, or strange noises during riding all signal spoke problems. Rim movement that wasn’t previously present indicates multiple loose spokes working together to compromise wheel integrity. If you notice any of these symptoms, perform a thorough spoke inspection before your next ride—continuing to ride risks catastrophic failure.

Danger of Ignoring Loose Spokes

Neglected loose spokes create a domino effect: one loose spoke transfers excessive load to its neighbors, causing them to loosen faster. This uneven stress concentration leads to rim buckling, cracks, and eventually complete wheel collapse. Even before total failure, poor spoke tension reduces handling precision, accelerates tire wear, and transmits damaging vibrations through your entire frame.

Solving Common Spoke Problems

Freeing Seized Nipples on Older Bikes

When spoke nipples refuse to turn due to corrosion, apply penetrating lubricant directly at the spoke-nipple junction and let it soak for 24-48 hours. Gently work the nipple back and forth with light pressure—never force it. If the nipple remains seized after treatment, replacement is usually necessary. Trying to force a seized nipple often breaks the spoke or damages the rim.

Overcoming Torque Wrench Limitations

On older wheels with corroded components, torque wrenches often measure seizure friction rather than actual tension. When your torque wrench clicks but the spoke still sounds loose, switch to the twang test for more reliable feedback. If multiple spokes show inconsistent tension despite proper torque readings, your wheel may need professional re-lacing with new components.

Pro Maintenance Strategies for Long-Lasting Wheels

Keep spokes clean by wiping them down after muddy or wet rides—dirt and moisture accelerate corrosion that leads to seized nipples. For riders in salt-heavy environments, apply a light corrosion inhibitor to spoke nipples after cleaning. Document your baseline tension settings after a fresh tune-up; significant deviations during future checks indicate developing problems before they become visible. By staying proactive with your spoke maintenance and addressing small issues immediately, you’ll enjoy reliable wheel performance season after season—keeping you safely on the trail rather than stranded with a wobbling wheel. Remember: knowing exactly how tight should dirt bike spokes be isn’t just technical knowledge—it’s your insurance against mid-ride disasters.