When your dirt bike engine starts losing compression or power, the cylinder is often the culprit. Dirt bike cylinder plating represents the most effective solution for restoring performance while dramatically extending engine life. Whether you’re a weekend warrior tearing up local trails or a competitive racer chasing podium finishes, understanding modern plating technologies can save you money and frustration. This guide cuts through the marketing hype to deliver actionable information about selecting, installing, and maintaining plated cylinders that deliver real-world performance benefits.

The punishing reality of off-road riding subjects cylinder walls to extreme conditions that quickly destroy unprotected surfaces. Fine dirt particles infiltrate the combustion chamber, creating an abrasive mixture that rapidly wears down traditional cast iron liners. High-RPM operation combined with variable loads causes thermal cycling that leads to cylinder distortion. Without proper protection, your engine’s performance degrades within just a few riding hours. Modern plating technologies solve these problems by creating surfaces that resist wear while maintaining optimal thermal properties for consistent power delivery.

Why NSC Plating Outperforms Traditional Cylinder Treatments

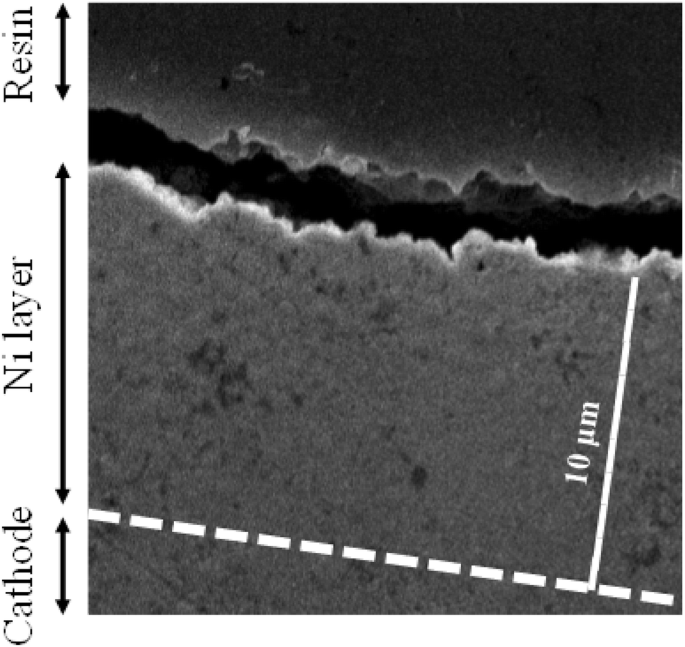

Nickel Silicon Carbide (NSC) plating creates a composite surface that combines nickel’s corrosion resistance with silicon carbide’s exceptional hardness. During the electroplating process, microscopic silicon carbide particles become permanently embedded in a nickel matrix, forming a surface that withstands the abrasive conditions of off-road riding far better than chrome or untreated aluminum.

The science behind NSC’s superiority lies in its dual-phase structure. The nickel matrix provides necessary ductility to accommodate thermal expansion while maintaining ring seal, while the silicon carbide particles—measuring just 1-2 microns in diameter—act as microscopic load-bearing elements that distribute mechanical stress. This combination delivers 3-4 times the wear resistance of conventional chrome plating, translating directly to extended service intervals.

How NSC Plating Improves Thermal Management

Unlike chrome plating which can create hot spots, NSC’s thermal conductivity characteristics help distribute heat more evenly across the cylinder wall. This thermal management capability:

- Reduces the risk of detonation during high-RPM operation

- Maintains consistent ring seal throughout the operating range

- Allows for more aggressive tuning without compromising reliability

- Prevents cylinder distortion that leads to power loss

Racers consistently report being able to maintain higher compression ratios with NSC-plated cylinders because the surface handles heat more effectively. This thermal stability means your engine delivers consistent power from the first lap to the last, rather than fading as temperatures climb.

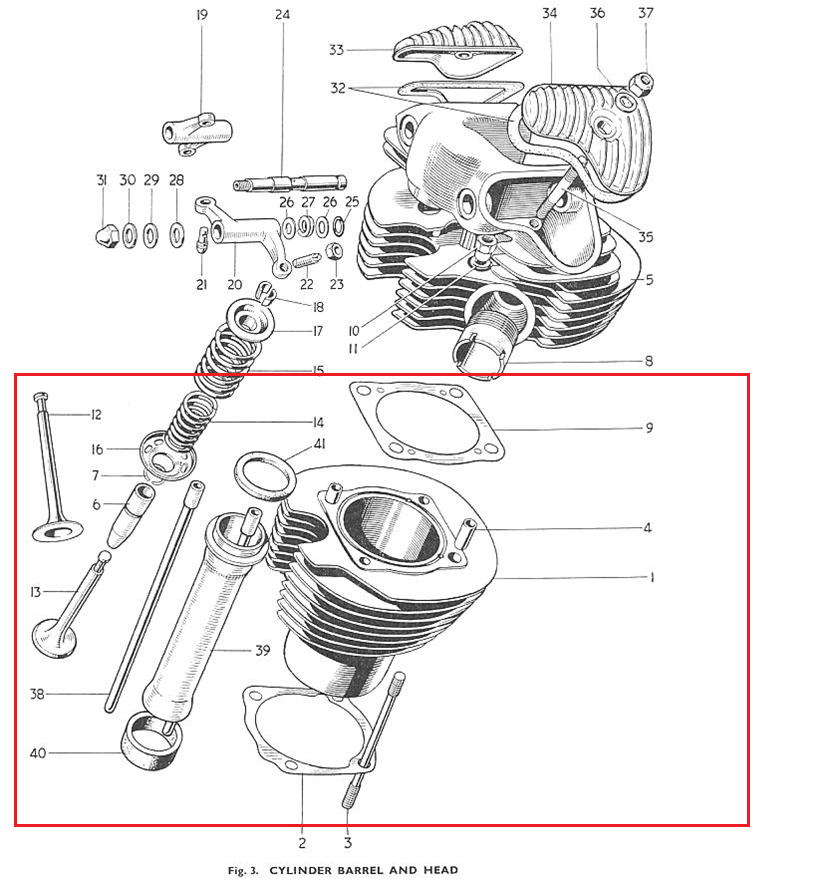

Precision Refurbishment: More Than Just Plating

Professional cylinder refurbishment involves multiple precision processes that work together to restore optimal performance. Simply applying plating to a worn cylinder won’t deliver expected results—the entire process must be executed with exacting standards.

Critical Steps in Professional Cylinder Refurbishment

- Complete disassembly and cleaning – Removes all carbon deposits and old plating residues

- Precision measurement – Identifies wear patterns, out-of-round conditions, and dimensional deviations

- Base machining – Corrects cylinder geometry before plating application

- Surface preparation – Creates optimal bonding surface for plating adhesion

- Plating application – Deposits the NSC composite at precisely controlled thickness

- Final honing – Creates the optimal cross-hatch pattern for ring seating

Common mistake to avoid: Skipping the base machining step to save money. A cylinder with significant wear requires proper machining before plating, otherwise the plating will simply follow the existing wear pattern, leading to premature failure.

Cylinder Exchange Programs: Minimize Downtime

For riders who can’t afford weeks without their bike, cylinder exchange programs provide a strategic advantage. These services maintain inventory of pre-plated cylinders ready for immediate installation, dramatically reducing downtime compared to custom rebuilds.

Exchange Program Advantages and Limitations

Advantages:

– Receive replacement cylinder within 1-3 business days

– Eliminate wait time for custom plating processes

– Often more cost-effective than full custom rebuilds

– Pre-tested for proper dimensions and plating quality

Limitations:

– May not match exact specifications of modified engines

– Limited availability for less common models

– Typically offer standard compression ratios unless specified

When selecting an exchange cylinder, verify the exact model compatibility and ask about the plating thickness. Some facilities offer “race-spec” versions with thicker plating for extreme applications, though these require careful matching with appropriate piston rings.

Essential Complementary Services

True performance optimization requires addressing the entire combustion system, not just the cylinder. The most effective plating providers offer complementary services that work synergistically with cylinder treatments.

Micro Polishing: The Critical Finishing Touch

Following plating application, micro polishing creates a mirror-like finish that significantly reduces friction. This process:

- Uses progressively finer abrasives to eliminate microscopic peaks

- Creates optimal surface texture for ring seating

- Reduces initial break-in time by 30-50%

- Lowers oil consumption by improving ring seal

Many shops include micro polishing as part of their premium plating packages, but always confirm this is included rather than treated as an add-on service.

CNC Head Porting for Complete System Optimization

A plated cylinder performs best when paired with properly ported cylinder heads. CNC-guided porting ensures:

- Precise replication of optimized port shapes

- Balanced airflow across all ports

- Customization for specific riding conditions

- Improved volumetric efficiency across the powerband

For two-stroke engines, specialized port timing adjustments work particularly well with plated cylinders to create broader power delivery. Many professional shops offer package deals combining cylinder plating with head work for comprehensive performance gains.

Evaluating Plating Service Providers

Not all plating services deliver equal results. The quality of your cylinder plating depends heavily on the facility’s equipment, processes, and expertise.

Key Questions to Ask Before Choosing a Provider

- What plating thickness do they apply? Optimal NSC thickness ranges from 0.004-0.006 inches for dirt bikes

- Do they perform in-house measurements? Precision measurement before and after plating is critical

- What quality control processes do they follow? Reputable shops provide measurement reports

- How do they handle surface preparation? Proper cleaning and activation determine plating adhesion

- What warranty do they offer? Quality providers typically warranty against plating failure

Pro tip: Request samples of their finished work. A quality-plated cylinder should have a uniform matte gray appearance without streaks or discoloration. Run your finger along the surface—it should feel consistently smooth without noticeable variations.

Maximizing Plated Cylinder Longevity

Your maintenance practices significantly impact how long your plated cylinder delivers peak performance. Even the best plating will fail prematurely with improper care.

Essential Maintenance Practices

- Break-in procedures: Follow manufacturer recommendations precisely—typically 2-3 hours of varied RPM operation

- Oil selection: Use high-quality synthetic two-stroke oil at recommended ratios (typically 32:1 to 40:1)

- Air filter maintenance: Clean and re-oil after every ride to prevent abrasive particles from entering the engine

- Compression checks: Monitor every 5-10 hours to detect developing issues early

- Cooling system maintenance: Ensure proper coolant flow to prevent overheating

Warning: Never use ceramic-coated piston rings with NSC-plated cylinders. The harder ceramic coating will rapidly wear the plating. Instead, use premium chrome or molybdenum rings specifically designed for plated surfaces.

Performance and Cost Analysis

While NSC plating represents a significant upfront investment, the long-term value proposition makes it worthwhile for serious riders. Consider these comparative metrics:

| Service Type | Initial Cost | Expected Service Interval | Cost Per Hour |

|---|---|---|---|

| Standard rebuild with cast iron liner | $250-$350 | 15-25 hours | $10-$23/hour |

| NSC plating rebuild | $450-$650 | 80-120 hours | $3.75-$8.13/hour |

The data shows NSC plating delivers 3-4 times the service life at roughly half the hourly cost. For competitive racers, the performance consistency throughout the service interval provides additional value that isn’t captured in simple cost-per-hour calculations.

Making Your Plating Decision

When selecting a plating service, match the solution to your riding style and performance goals:

- Recreational trail riders: Standard NSC plating with micro polishing provides excellent value

- Competitive amateurs: Consider thicker plating (0.006″) for extended service intervals

- Professional racers: Opt for race-spec plating combined with custom porting

The initial investment in quality cylinder plating pays dividends through consistent performance, reduced downtime, and lower long-term maintenance costs. For dirt bike owners serious about maximizing their machine’s potential, NSC plating represents one of the most cost-effective performance upgrades available.

Final tip: Document your cylinder’s performance after installation. Track compression readings, oil consumption, and power characteristics over time. This data helps identify when maintenance is needed and provides valuable feedback for future rebuilds. With proper care, your plated cylinder will deliver reliable performance season after season, keeping you focused on the trail rather than the workshop.