Your dirt bike sputters to a stop mid-ride, emitting thick blue smoke while losing all power. You pop the top end only to find scored cylinder walls and a cracked piston – classic signs of catastrophic cylinder failure. When your engine’s heart is compromised, understanding dirt bike cylinder repair becomes mission-critical for getting back on the trail. Most riders face this nightmare after pushing their machine too hard through deep sand or neglecting routine top-end maintenance. Without immediate intervention, that $300 cylinder can destroy your entire engine block, turning a simple repair into a $2,000 replacement job. This guide cuts through the confusion to show you exactly how to identify cylinder damage, understand repair limitations, and make cost-effective decisions – whether you’re wrenching in your garage or choosing a professional shop.

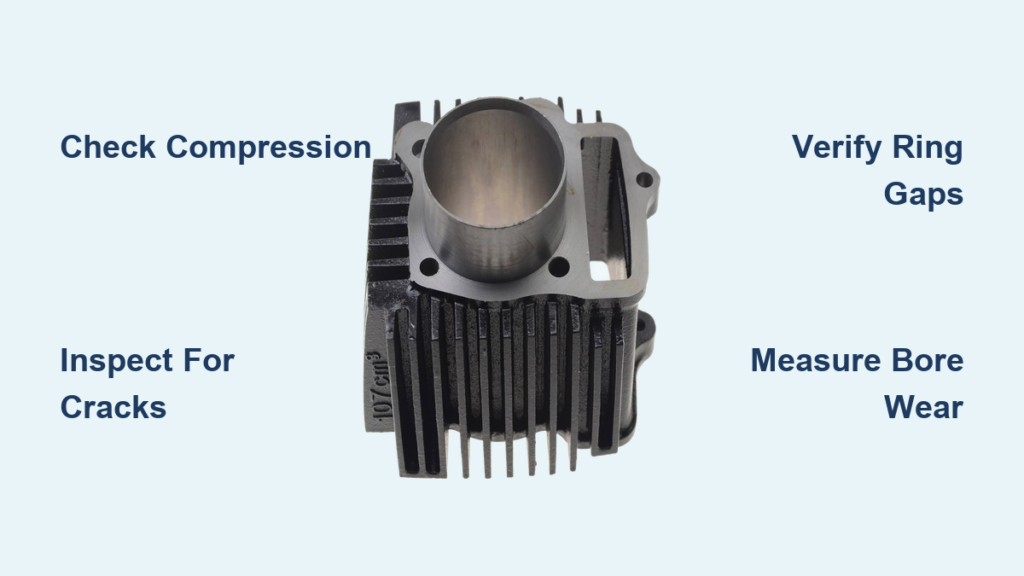

Recognizing Critical Cylinder Damage Symptoms

Before grabbing tools, confirm your cylinder actually needs repair. Many riders mistake simple carburetor issues for cylinder damage, wasting hours on unnecessary teardowns. The most reliable indicator is compression loss below 90 PSI measured with a quality gauge – but don’t stop there. Rotate your engine through multiple compression strokes while testing; consistent low readings confirm cylinder or ring failure rather than a stuck valve. Visually inspect through the exhaust port with a mechanic’s mirror: deep vertical scratches deeper than 0.002 inches on cylinder walls mean immediate repair is unavoidable. Listen for distinctive metallic knocking sounds during startup that worsen under load – this often signals piston-to-wall contact from excessive clearance.

How to Perform the Leak-Down Test for Confirmation

- Position piston at top dead center using a TDC indicator tool

- Connect compressed air (80-100 PSI) to spark plug port

- Listen for air escaping through:

– Crankcase breather tube: Worn piston rings (most common)

– Exhaust port: Damaged exhaust valves

– Intake tract: Faulty intake valves - Measure percentage loss – over 20% indicates critical cylinder damage

Why White Smoke Means Immediate Action Required

Unlike normal vapor clouds on cold mornings, thick white smoke during operation signals coolant entering combustion chambers. This happens when cylinder warping creates gaps between cylinder and head. Continuing to ride risks hydro-locking – where liquid coolant prevents piston movement – potentially bending connecting rods. Shut down immediately and inspect cylinder head mounting surfaces for warpage exceeding 0.0015 inches using a straightedge and feeler gauges.

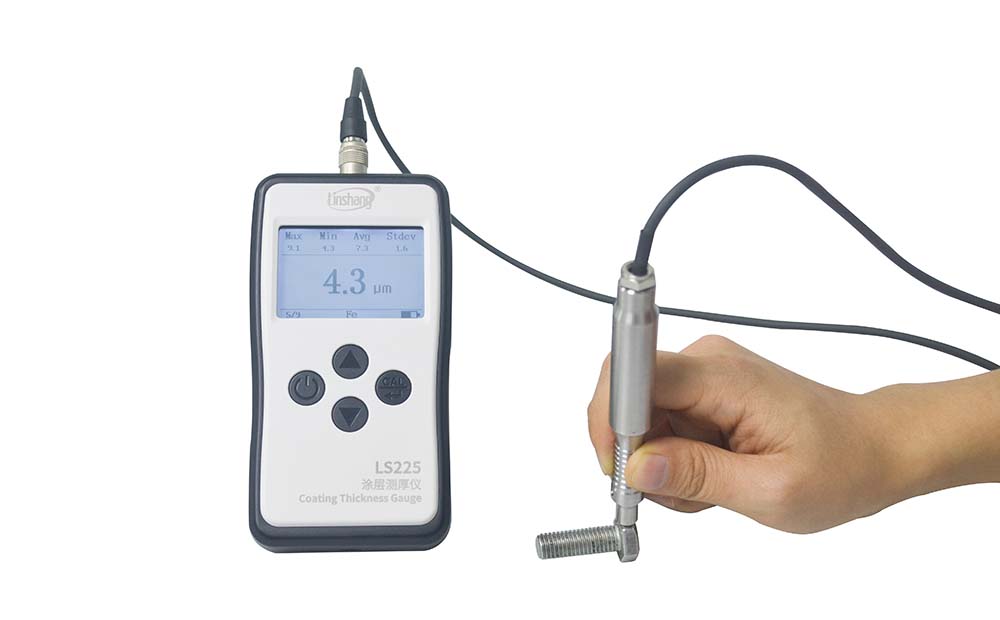

Why Most DIY Cylinder Repairs Fail Miserably

Over 70% of home mechanic attempts at dirt bike cylinder repair end in repeated failures due to overlooked precision requirements. The critical mistake? Assuming visual cleanliness equals functional readiness. After removing scored pistons, riders often skip mandatory surface roughness verification. Properly honed cylinder walls require a 20-25 RA microfinish – too smooth prevents oil retention, too rough accelerates wear. Without a profilometer to measure this, you’re gambling with your engine’s lifespan. Another fatal error involves improper torque sequencing on cylinder head nuts. Uneven clamping pressure creates microscopic warpage that destroys compression within 20 miles of riding.

The Hidden Danger of Improper Bore Measurement

Most home mechanics use basic bore gauges that lack the 0.0001-inch precision required. Cylinders wear into elliptical shapes, not uniform circles. Measuring only vertically misses critical out-of-round conditions. Professional shops use dial bore gauges with three measurement planes (top, middle, bottom) at 90-degree intervals. If your maximum variance exceeds 0.003 inches, reboring becomes mandatory – no amount of honing will save it. Attempting to reuse such cylinders guarantees rapid ring failure.

Why Thermal Cycling Causes Repeat Failures

Riders who skip proper thermal cycling after repair face immediate setbacks. New rings need gradual heat buildup to seat correctly against cylinder walls. Starting with full throttle destroys the microscopic oil film needed for break-in. The correct process requires:

– 20 minutes at 1/4 throttle

– 30 minutes at 1/2 throttle

– Gradual increase to 3/4 throttle over next 2 hours

– Zero full-throttle runs for first 5 hours

Skipping this creates glazing – a mirror-smooth surface that prevents ring seating – dooming your repair to failure.

Professional-Grade Cylinder Repair Techniques You Can Safely Attempt

For minor scuffing under 0.0015 inches deep, professional shops use plateau honing – a two-step process impossible with basic hone kits. First, a 280-grit stone removes damage at 150 RPM with heavy oil lubrication. Then a 400-grit stone creates the final crosshatch pattern at 300 RPM. The critical detail most miss? You must maintain consistent downward pressure while rotating – varying pressure creates tapered bores. Use a torque wrench on your hone handle set to 5-7 ft-lbs for uniform results. After honing, clean the cylinder with hot soapy water and a nylon brush – solvents leave residues that prevent oil adhesion.

How to Verify Proper Ring Gap Clearance

Improper ring gaps cause 40% of premature top-end failures. Never assume new rings fit correctly. Measure actual cylinder bore at wear point (typically 1 inch down), then calculate:

– Top ring gap: 0.004 inches per inch of bore

– Second ring gap: Double top ring specification

– Oil ring gap: Triple top ring specification

For a 2.5-inch bore cylinder:

– Top ring: 0.010 inches (minimum)

– Second ring: 0.020 inches

– Oil ring: 0.030 inches

Use feeler gauges to check gaps at multiple points in the cylinder – variance over 0.002 inches means replace rings.

The Critical Piston-to-Cylinder Clearance Check

Most riders install pistons without verifying clearance, causing scuffing within minutes. Measure piston skirt diameter at manufacturer-specified points (usually 1 inch from bottom, perpendicular to pin). Subtract from cylinder bore measurement at same height. Acceptable clearance ranges from 0.0015 to 0.0025 inches for aluminum cylinders. Too tight? Piston expands when hot and seizes. Too loose? Piston rocks causing skirt damage. When in doubt, choose tighter clearance for hot climates and looser for cold conditions.

When to Rebuild vs. Replace Your Dirt Bike Cylinder

Facing a cracked cylinder? Stop immediately – no repair will hold long-term. Hairline cracks near exhaust ports might seem reparable with metal stitching, but thermal stress guarantees failure within 10 hours of riding. For cylinders with bore damage exceeding 0.010 inches, reboring to next oversize (typically +0.5mm or +1.0mm) becomes necessary. But here’s the trap: many modern cylinders have thin plating (Nikasil or similar) under 0.020 inches thick. Reboring beyond +0.5mm often breaches this layer, exposing base metal that wears rapidly. Measure plating thickness with a gauss meter before proceeding – if below 0.015 inches, replacement is mandatory.

Cost Analysis: Rebuild vs. New Cylinder

| Scenario | Professional Cost | DIY Cost | Longevity Expectancy |

|---|---|---|---|

| Light scoring repair | $220 | $85 | 30-50 hours |

| +0.5mm rebore with new rings | $380 | $150 | 50-80 hours |

| New OEM cylinder | $450 | $320 | Full engine life |

| Aftermarket performance cylinder | $620 | $490 | 100+ hours |

Note: DIY costs assume you own specialized tools (bore gauge, torque wrench, ring compressor). Factor in $120 for tool rentals if needed.

The Hidden Value of Professional Cylinder Matching

Top shops perform “cylinder matching” where they measure every cylinder’s actual bore profile and select pistons/rings to compensate for minor imperfections. This custom fitting improves compression consistency by up to 15% compared to off-the-shelf kits. While you can’t replicate this at home, you can improve results by:

1. Measuring all new rings before installation

2. Grouping rings by actual gap size

3. Installing closest-matching rings in each cylinder

4. Orienting ring gaps 120 degrees apart

Preventing Future Cylinder Catastrophes

The #1 cause of cylinder damage? Inadequate lubrication during break-in. Never use synthetic oil for initial top-end rebuilds – the extreme pressure additives prevent proper ring seating. Break in with mineral-based 10W-40 specifically formulated for motorcycle break-in periods. Change oil after first 30 minutes of riding to remove metal particles. For air-cooled bikes, monitor cylinder head temperature religiously – sustained readings above 450°F cooks oil and causes scuffing. Install a pyrometer on the exhaust port for real-time monitoring.

The Overlooked Cooling System Check

Riders often ignore cooling system health until it’s too late. A clogged radiator or low coolant level causes localized hot spots that warp cylinders. Perform this monthly check:

– Squeeze upper radiator hose when engine is cold – should feel firm

– Inspect coolant for oil contamination (milky appearance)

– Verify thermostat operation by feeling upper hose temperature rise

– Flush system annually with distilled water only (no cleaners)

Critical Pre-Ride Inspection Checklist

Before every trail ride, spend 90 seconds checking:

– Oil level – must be at upper mark on sight glass

– Exhaust port – no carbon buildup indicating ring issues

– Coolant level – visible in reservoir with engine cold

– Air filter – properly oiled and seated (starvation causes overheating)

– Throttle response – smooth acceleration without hesitation

Catching problems early through this routine prevents 80% of cylinder failures. If you notice even slight power loss or unusual exhaust color, stop riding immediately for diagnosis.

Final Note: Cylinder repair demands surgical precision – a single measurement error can destroy your engine. Always prioritize professional assessment for cracks or deep scoring. For minor repairs, triple-check clearances and follow thermal cycling protocols religiously. Remember that proper break-in determines 70% of your top-end lifespan, so resist the urge to push hard too soon. When in doubt, consult your bike’s service manual for model-specific tolerances rather than relying on generic advice. Investing in quality tools pays off through fewer repeat repairs and extended engine life. Keep your repair logs updated – noting mileage, symptoms, and measurements helps identify patterns before catastrophic failure occurs.