You’re tearing down a trail when suddenly your dirt bike sputters—the engine coughs, the rear wheel loses traction, and you’re left pushing through the mud. If you’ve ever wondered why this happens or how these high-performance machines transform throttle input into explosive power, you’re not alone. Understanding how a dirt bike works is critical for riders who want to troubleshoot issues, optimize performance, or simply appreciate the engineering beneath them. Unlike street motorcycles, dirt bikes prioritize lightweight agility, raw power delivery, and suspension that absorbs brutal terrain. In this guide, you’ll learn exactly how dirt bike engines ignite combustion, how power transfers to the rear wheel, and why suspension systems make or break your ride—no engineering degree required.

Two-Stroke vs. Four-Stroke Engine Operation

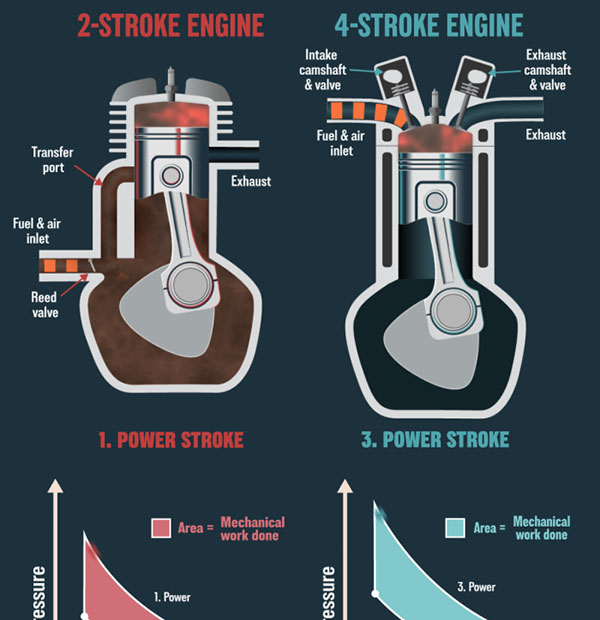

Dirt bikes primarily use two-stroke or four-stroke engines, each with distinct power delivery and maintenance needs. Two-stroke engines complete a power cycle in just two piston movements (up and down), creating explosive acceleration but requiring oil mixed directly with fuel. As the piston rises, it compresses the air-fuel-oil mixture in the combustion chamber while simultaneously drawing fresh mixture into the crankcase. When the piston drops after ignition, it uncovers exhaust and intake ports, expelling burnt gases while fresh mixture floods the crankcase—ready for the next compression stroke. This simplicity makes two-strokes lighter and more powerful for their size but thirstier for fuel and louder.

Why Four-Stroke Engines Dominate Modern Trails

Four-stroke engines (like those in the Honda CRF450R) use four piston strokes to complete one power cycle, mimicking car engines but optimized for dirt. Here’s the sequence:

1. Intake stroke: Piston drops, opening the intake valve to suck in air-fuel mixture

2. Compression stroke: Piston rises, compressing the mixture with both valves closed

3. Power stroke: Spark plug ignites mixture, forcing piston down violently

4. Exhaust stroke: Piston rises again, pushing out burnt gases through the open exhaust valve

This design delivers smoother, more controllable power and meets stricter emissions standards—explaining why 90% of new competition bikes use four-strokes. However, they’re heavier due to complex valve trains (cams, lifters, springs) and require precise valve clearance adjustments every 30 hours of riding.

Power Transfer: Clutch, Transmission & Final Drive

How the Clutch Manages Explosive Power

Dirt bike clutches are wet multi-plate designs bathed in engine oil, critical for handling sudden power surges. When you pull the clutch lever:

– Steel and friction plates separate inside the clutch basket

– Engine rotation disconnects from the transmission

– You can shift gears without grinding

Pro Tip: Feathering the clutch (partially engaging it) modulates power delivery on slippery terrain—like using a light brake while accelerating. Never “ride the clutch” (holding it partially engaged) for long periods; it burns friction plates.

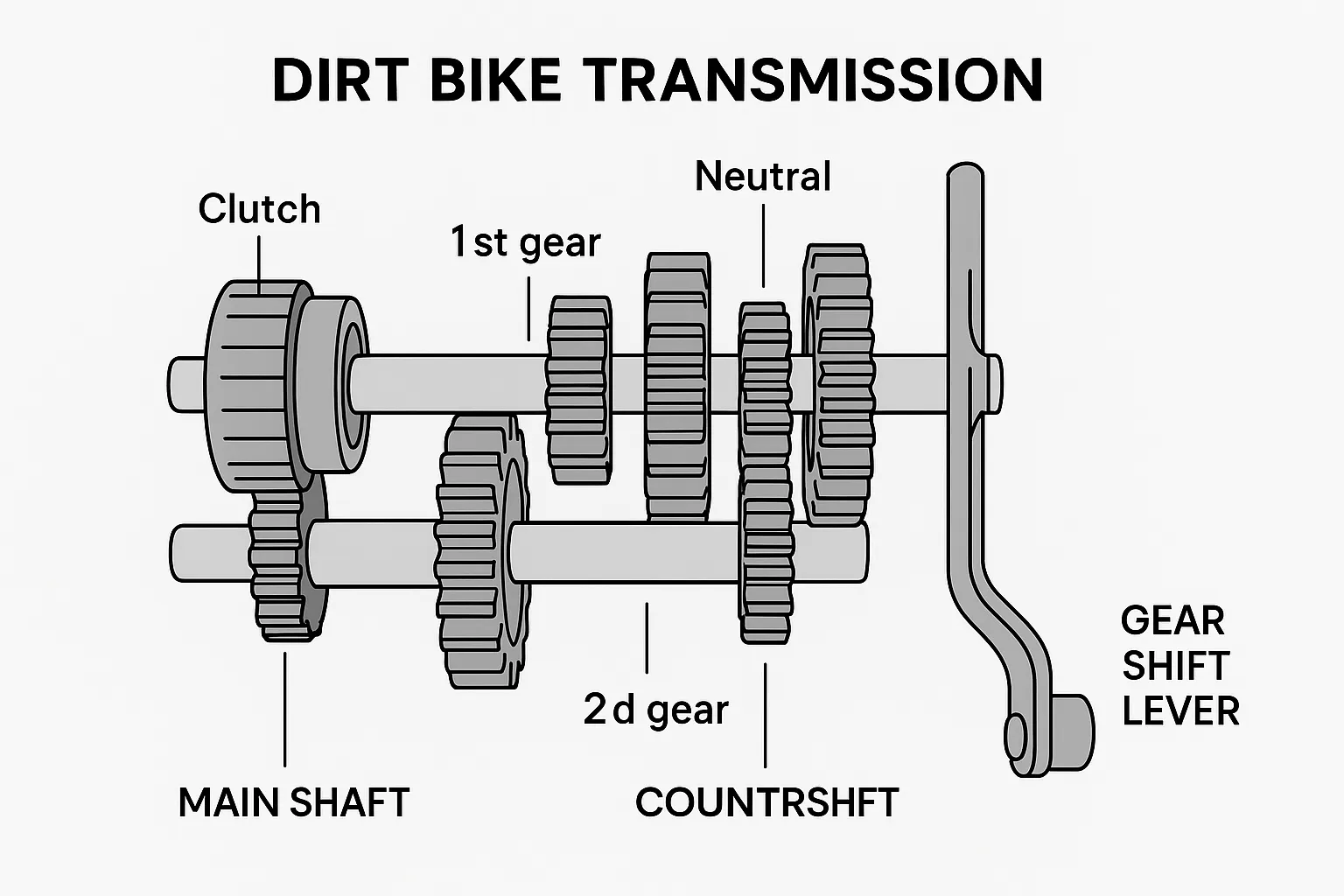

Gearbox Mechanics for Instant Acceleration

Dirt bikes use constant-mesh transmissions where gears are always engaged but rotate freely until locked by shift forks. Kicking the shift lever moves these forks, sliding dog clutches to lock specific gears to the output shaft. Most trail bikes have 5 gears:

– 1st gear: Maximum torque for steep climbs (wheel speed = 1/3 engine speed)

– 5th gear: High-speed cruising (wheel speed nearly matches engine RPM)

Critical mistake: Skipping gears (e.g., 2nd to 4th) causes violent drivetrain shock. Always shift sequentially.

Chain Drive vs. Shaft Drive: Why Chains Rule Off-Road

99% of dirt bikes use chain final drives—not shafts—for three reasons:

1. Weight: Chains save 10+ lbs vs. shaft systems

2. Flexibility: Chains accommodate rear suspension movement

3. Cost: $20 chain replacements vs. $500+ shaft repairs

Maintenance must: Adjust chain tension weekly (½–1 inch of slack). A loose chain jumps sprockets; a tight one strains bearings. Lubricate after every muddy ride with off-road-specific chain lube.

Suspension: The Secret to Conquering Rough Terrain

Front Fork Physics: Telescopic vs. Upside-Down

All modern dirt bikes use telescopic forks, but premium models (like KTM 450 SX-F) flip them upside-down (USD). Here’s why:

– USD forks: Stanchions (thick tubes) are at the top, reducing unsprung weight by 15%

– Conventional forks: Stanchions hang below—cheaper but flexes more on hard impacts

When you hit a bump:

1. Outer tubes compress into inner tubes

2. Compression damping (oil forced through small holes) controls how fast forks collapse

3. Rebound damping regulates how quickly forks extend back out

Red flag: If forks dive excessively on braking, compression damping is too soft. If they “pack down” on successive bumps, rebound is too fast.

Rear Shock Tuning for Weight Transfer

The rear shock connects the swingarm to the frame and handles 70% of suspension duty. Key components:

– Spring rate: Stiffer springs for heavier riders (e.g., 5.2 kg/mm for 200+ lbs)

– Preload adjuster: Compresses spring to set sag (ideal: 100–110mm for trail riding)

– High-speed compression: Controls big-hit absorption (rocks, drops)

– Low-speed compression: Manages body weight shifts (cornering, braking)

Field test: Sit on the bike in riding gear. Have a friend push down hard on the rear fender. If the shock bottoms out harshly, increase preload. If it barely compresses, soften the spring.

Fuel, Ignition & Exhaust Systems

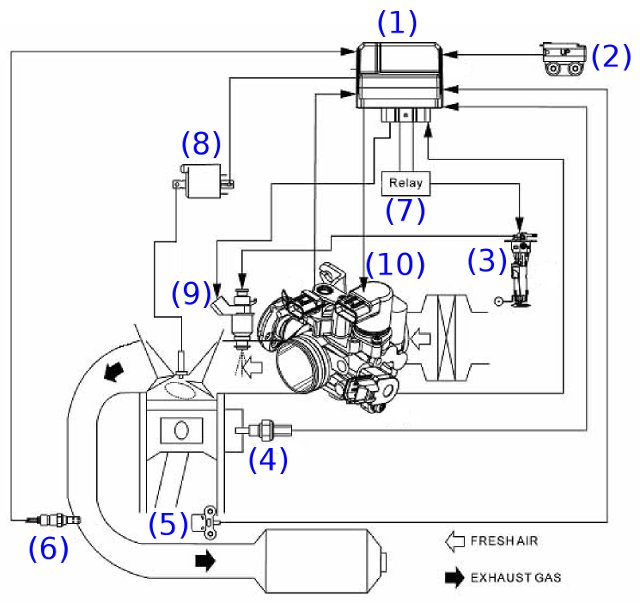

Carburetors vs. Fuel Injection: Tuning Realities

While fuel injection dominates new bikes (e.g., Yamaha YZ250F), carbureted two-strokes (like Yamaha YZ125) remain popular for simplicity. Carburetors mix air and fuel via jets:

– Pilot jet: Controls idle/throttle response (replace if bike stalls at low RPM)

– Main jet: Governs full-throttle performance (lean = overheating; rich = fouled plug)

Pro insight: At high altitudes, reduce jet size by 2–4 numbers—thinner air requires less fuel.

Exhaust Systems: More Than Just Noise

Two-stroke exhausts use expansion chambers to boost power:

1. Pressure wave from combustion shoots down the pipe

2. Chamber shape reflects a negative wave back to the cylinder

3. This vacuum pulls out more exhaust gases and draws in fresh mixture

Four-strokes rely on tuned header lengths for scavenging efficiency. Never remove baffles—it disrupts timing waves and reduces low-end torque.

Braking & Handling Essentials

Hydraulic Disc Brakes: Stopping Power on Demand

Dirt bikes use hydraulic brakes because they’re immune to mud/water (unlike drum brakes). When you squeeze the lever:

– Master cylinder pushes fluid through lines

– Fluid pressure forces caliper pistons against rotor

– Sintered brake pads (metal-infused) work when wet but wear rotors faster

Critical fix: Air bubbles in lines cause spongy levers. Bleed brakes annually with DOT 4 fluid.

Geometry Secrets: Why Dirt Bikes Turn Like Knives

Three chassis angles define handling:

– Rake: Steering head angle (26°–28°)—smaller = quicker turns

– Trail: Distance between steering axis and tire contact (4–5 inches)—more trail = stable at speed

– Seat height: Lower = easier to dab feet (e.g., 36″ vs. 38″ on tall bikes)

Weight transfer trick: Shift body weight behind the seat on steep descents to keep the front wheel planted.

Maintenance Checklist for Peak Performance

| System | Critical Check | Frequency |

|---|---|---|

| Engine | Valve clearance (4-strokes) | Every 30 hours |

| Suspension | Oil level/leaks in forks/shock | Every 10 hours |

| Drivetrain | Chain tension/lube | After every ride |

| Brakes | Pad thickness/rotor warping | Weekly |

| Tires | Tread depth/pressure | Before each ride |

Pro tip: Keep a “ride log” noting handling quirks (e.g., “forks felt harsh on jumps”). This tracks wear patterns before failures occur.

When to Seek Professional Help

While basic maintenance is DIY-friendly, certain issues demand a mechanic:

– Engine knocking: Could indicate piston seizure (stop riding immediately)

– Suspension oil leaks: Requires disassembly and seal replacement

– Electrical faults: CDI unit or stator failures need diagnostic tools

Ignoring these risks catastrophic damage—like a seized engine costing $1,200+ to rebuild.

Final Takeaways: Ride Smarter, Not Harder

Mastering how a dirt bike works transforms you from a rider into a pilot who anticipates problems before they strand you. Remember: two-strokes deliver raw simplicity but demand meticulous fuel mixing; four-strokes offer control at the cost of weight; chain drives need weekly love; and suspension settings are personal as your fingerprint. Invest 20 minutes after each ride checking chain tension, tire pressure, and brake function—this prevents 80% of trailside breakdowns. Now that you understand the symphony of combustion, power transfer, and terrain absorption beneath you, hit the trails with confidence. Your bike isn’t just machinery; it’s a finely tuned partner in every jump, turn, and victory lap.

Next Step: Bookmark this guide for your next maintenance session, and share it with a fellow rider who’s still guessing why their bike bogs on takeoff. For deeper dives, explore our companion articles: Dirt Bike Suspension Tuning for Beginners and Two-Stroke vs. Four-Stroke: Which Wins on Your Trail?