Ever wondered how some dirt bike riders shift gears without ever touching a clutch lever? Semi-automatic dirt bikes solve this mystery with clever engineering that keeps you engaged with gear selection while eliminating the complexity of manual clutch operation. These machines provide the perfect balance for trail riders who want the satisfaction of shifting gears without the constant hand coordination required by traditional dirt bikes. Understanding how does a semi automatic dirt bike work reveals why they’ve become increasingly popular among beginners and casual trail riders who prioritize enjoyment over competitive performance. This guide breaks down the exact mechanics that make these bikes function so smoothly on the trail.

Inside the Automatic Clutch: How Centrifugal Force Replaces Your Left Hand

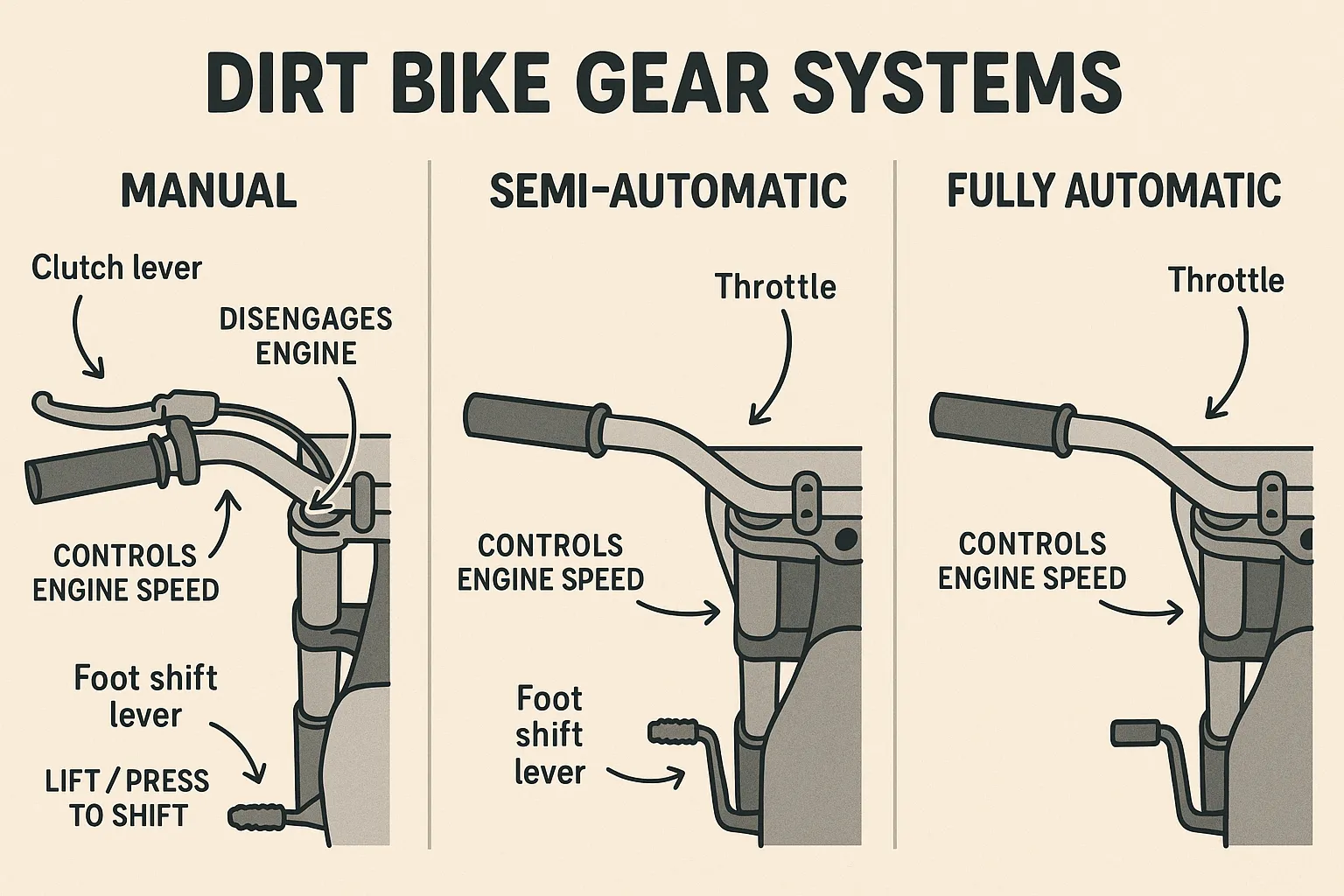

The automatic clutch is the true innovation that defines semi-automatic dirt bikes, completely eliminating the need for a clutch lever while maintaining precise power delivery. Unlike manual systems requiring constant hand coordination, these bikes use either centrifugal force or hydraulic pressure to automatically engage and disengage power transfer based on engine speed. When you twist the throttle and RPM increases, the clutch gradually connects the engine to the transmission without any rider input. The magic happens through internal mechanisms that respond to engine speed changes, allowing seamless power delivery exactly when you need it.

Centrifugal Clutch Mechanics: Weighted Balls and Engine RPM Connection

Centrifugal clutches rely on weighted components inside the clutch assembly that move outward as engine speed increases. These small weights—either balls or rollers—push against spring pressure to gradually squeeze the clutch plates together as RPM rises. At idle speed, spring tension keeps the plates separated, preventing power transfer to the transmission. But as you open the throttle, centrifugal force overcomes the springs, pressing the plates together to connect engine power to the rear wheel. During gear shifts, RPM naturally drops momentarily, allowing the springs to separate the plates just long enough for the gears to change before re-engaging automatically.

Hydraulic Automatic Systems: Fluid Pressure vs. Mechanical Engagement

Some higher-end semi-automatic dirt bikes replace centrifugal mechanisms with hydraulic systems that use fluid pressure instead of mechanical force. These systems contain a pump driven by the engine that increases pressure as RPM rises, gradually engaging the clutch plates. The hydraulic approach provides more consistent engagement across different temperatures and riding conditions compared to centrifugal designs. While both systems achieve the same goal of automatic clutch operation, hydraulic versions typically offer smoother power delivery and more precise engagement points, though they may require slightly more maintenance than their centrifugal counterparts.

Mastering Foot Shifting Without a Clutch Lever

Despite lacking a clutch lever, semi-automatic dirt bikes still require active gear selection through a foot-operated shifter—this is where your engagement with the machine remains vital. The shifting pattern follows standard motorcycle convention: press down for first gear, find neutral in the half-step between first and second, then tap upward for subsequent gears. When you tap the shifter with your foot, the automatic clutch momentarily disengages just long enough for the gear change to occur, then re-engages seamlessly without any rider input required.

Downshifting to First Gear: The Critical Starting Point

Starting from a stop requires pressing the gear lever fully downward to engage first gear. Unlike manual bikes where you’d simultaneously pull the clutch lever, semi-automatic systems handle this automatically. As you gradually apply throttle, the centrifugal or hydraulic clutch engages smoothly, propelling you forward without stalling. This eliminates the most common beginner mistake—releasing the clutch too quickly—making first gear engagement nearly foolproof. The system ensures smooth power delivery even with aggressive throttle inputs, allowing you to focus entirely on balance and steering as you begin moving.

Upshifting Technique: When to Tap for Smooth Power Delivery

As your speed increases, tap the gear lever upward with the ball of your foot to shift to higher gears. The automatic clutch disengages during each shift, allowing the transmission to change ratios without interrupting power flow, then re-engages smoothly once the new gear is selected. Listen for engine pitch changes rather than counting shifts—when the engine sounds strained at high RPM, it’s time to upshift. Downshifting works the same way in reverse, providing additional engine braking for descents or more torque for climbs. This intuitive shifting process becomes second nature with minimal practice, letting you concentrate on trail navigation rather than clutch coordination.

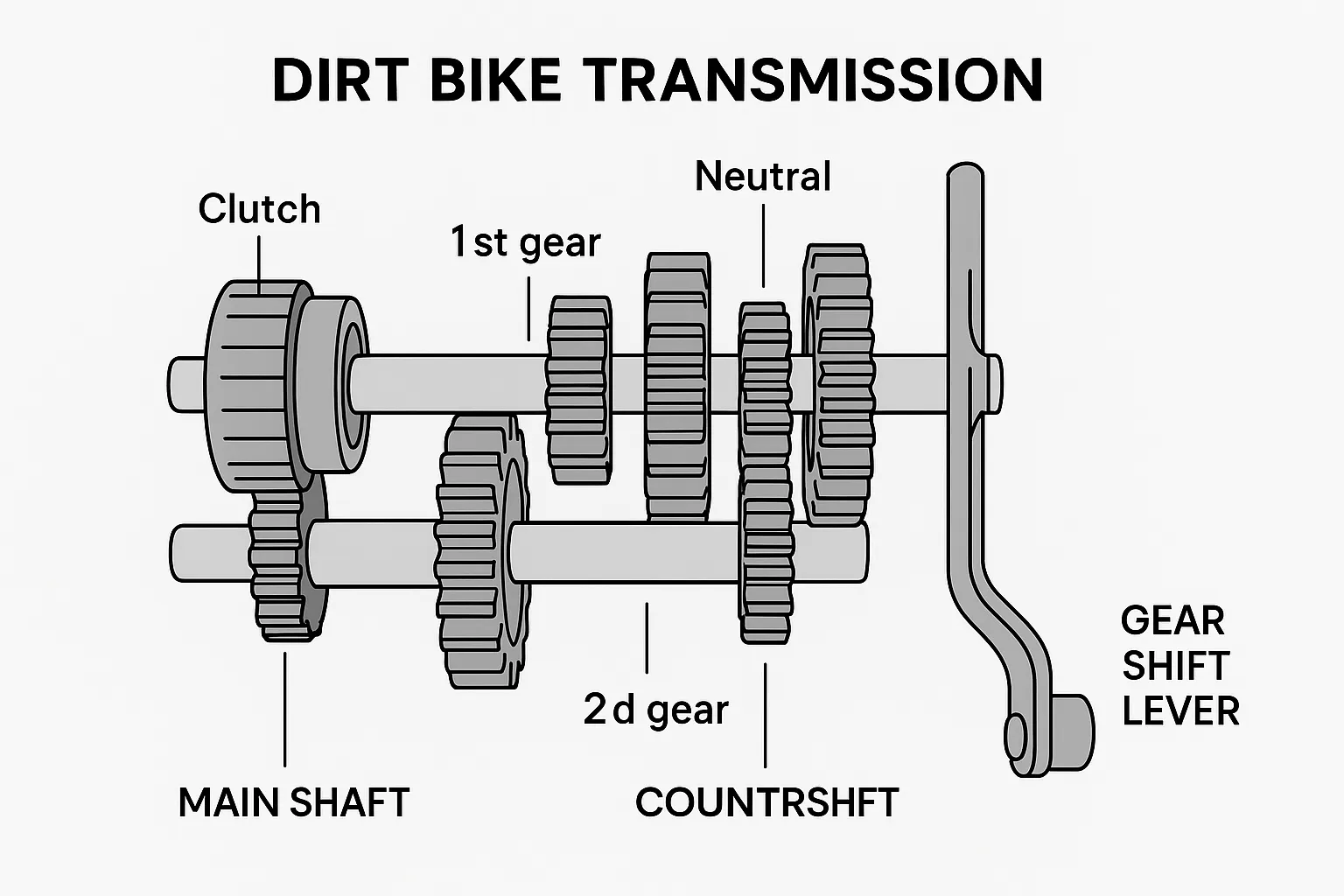

Essential Semi-Automatic Transmission Components Explained

Semi-automatic dirt bikes share many transmission components with manual models, with the key difference being how clutch engagement is controlled rather than how gears function mechanically.

Gearbox Ratios: Why 4-6 Gears Matter for Trail Riding

The transmission contains four to six forward gears with ratios optimized for different trail conditions. Lower gears (first and second) provide high torque for climbing steep hills and navigating technical terrain, while higher gears (third through sixth) allow efficient cruising on flat sections. The exact number of gears varies by model, with entry-level bikes often featuring four speeds while more advanced models offer five or six for better speed range coverage. This gear selection capability—combined with automatic clutch operation—is what gives semi-automatic bikes their unique balance of rider engagement and simplicity.

Automatic Clutch Assembly: The Sealed Maintenance-Free Design

This critical component replaces the traditional lever-and-cable system with a self-contained mechanism that engages based on engine speed. Multiple clutch plates stack together with either spring pressure or hydraulic control determining their grip on the transmission shaft. Most automatic clutch assemblies are sealed units requiring minimal maintenance beyond periodic inspection, making them more reliable than manual clutch systems that need frequent adjustment. The design ensures smooth power delivery without sudden jerks or wheel spin during engagement, providing consistent performance across various riding conditions.

3 Key Advantages of Semi-Automatic Over Manual Dirt Bikes

Eliminating Stalls: How Beginners Gain Confidence Faster

By removing clutch coordination from the equation, semi-automatic dirt bikes dramatically reduce the learning curve for new riders. Beginners can focus entirely on throttle control, balance, and obstacle navigation without worrying about stalling. This accelerated learning builds confidence quickly and creates more positive early experiences that encourage continued riding. Many first-time riders who might have quit after struggling with manual clutch operation find success with semi-automatic systems, staying engaged with the sport longer.

Reducing Hand Fatigue on Technical Trails

Technical trail riding with frequent stops, tight turns, and speed variations demands constant clutch operation on manual bikes, leading to hand and arm fatigue that shortens riding sessions. Semi-automatic bikes eliminate this fatigue source entirely, allowing riders to maintain a relaxed grip for longer periods. Younger riders who lack hand strength benefit particularly from this feature, as they can enjoy extended trail time without discomfort or compromised control.

Who Should Choose a Semi-Automatic Dirt Bike (And Who Shouldn’t)

Perfect Matches: Young Riders and Trail Enthusiasts

Young beginners represent the ideal candidates for semi-automatic dirt bikes. These riders face enough challenges learning balance and throttle control without adding clutch coordination. Semi-automatic machines let them focus on fundamental skills while still learning about gear selection, accelerating their development without frustration. Adult trail riders who prioritize enjoyment over competition also benefit from the simplified operation that keeps them engaged with gear selection while removing clutch management from the equation.

Consider Manual Instead: Competitive Riders and Performance Seekers

If your goal is competitive racing or pushing performance boundaries, manual transmissions remain the better choice. Racing demands precise control over every aspect of power delivery that semi-automatic systems cannot provide. The inability to intentionally slip the clutch for starts, corner exits, and technical sections places semi-automatic bikes at a competitive disadvantage. For riders pursuing podium finishes or advanced skills development, the complete control of a manual transmission proves essential despite the steeper learning curve.

Critical Semi-Automatic Maintenance Checklist

Oil Change Frequency: Why Dirt Bikes Need More Frequent Service

Regular oil changes form the foundation of proper transmission maintenance. Dirt bikes typically require oil changes every 10-20 hours of operation due to demanding off-road conditions—significantly more frequent than street motorcycles. Clean oil lubricates and protects all internal transmission components, while dirty or degraded oil accelerates wear on the automatic clutch assembly and gear mechanisms. Always use manufacturer-recommended oil specifications to ensure proper clutch engagement and transmission protection.

Chain and Sprocket Care: Preventing Costly Transmission Damage

Chain maintenance remains equally important for semi-automatic machines as for manual ones. Check chain tension before every ride and clean/lubricate after each trail session to prevent accelerated wear. A properly maintained chain ensures smooth power transfer from the transmission to the rear wheel, while neglect can cause chain jump, sprocket damage, and even transmission failure. Inspect sprockets regularly for worn teeth and replace them before they cause chain damage or unreliable operation.

Semi-automatic dirt bikes deliver an accessible yet engaging riding experience by automating the clutch while preserving gear selection. Understanding how does a semi automatic dirt bike work helps you appreciate this thoughtful engineering compromise that opens the sport to riders who might otherwise struggle with manual transmission complexity. Whether you’re a beginner seeking confidence on the trail or an adult rider prioritizing enjoyment over competitive performance, these machines offer a compelling middle ground between automatic simplicity and manual control. By eliminating clutch coordination while maintaining rider engagement through gear selection, semi-automatic dirt bikes provide a unique riding experience perfectly suited to trail enthusiasts who want to focus on the journey rather than mechanical management.