That frustrating moment when you’re ready to ride but your 2-stroke dirt bike won’t fire up—it’s enough to ruin your entire day. Whether you’re a weekend warrior or an experienced rider, knowing exactly how to kickstart a 2 stroke dirt bike properly separates those who spend more time riding from those stuck on the sidelines. The good news is that with the right technique, even a stubborn cold 2-stroke will roar to life consistently. In this guide, you’ll learn the precise method professional riders use to kickstart their 2-stroke dirt bikes on the first try, every time—no more sore legs or wasted riding time.

Most riders make critical mistakes during the kickstarting process that prevent their bikes from starting reliably. From incorrect choke usage to improper kick technique, these errors compound until your bike becomes increasingly difficult to start. By the end of this article, you’ll understand exactly why your 2-stroke won’t start, how to diagnose common starting issues, and the step-by-step process to kickstart your dirt bike successfully regardless of temperature or conditions. Let’s transform your starting experience from frustrating to flawless.

Proper Pre-Kickstart Bike Preparation Checklist

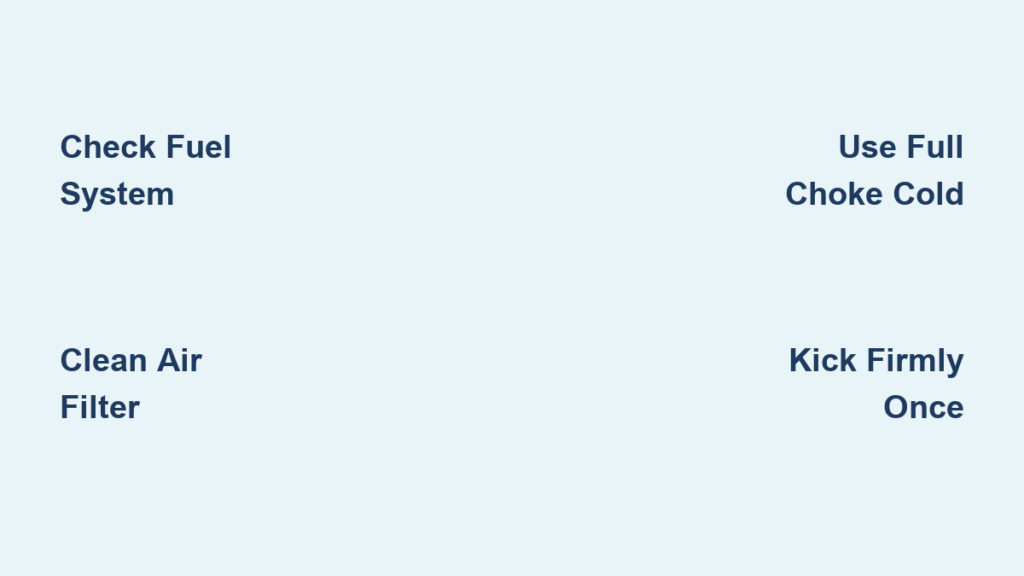

Before you even touch the kickstarter, your 2-stroke dirt bike must be in the correct starting configuration. Rushing this step is why most riders struggle with cold starts and inconsistent performance.

Fuel System Verification Steps

Confirm your fuel system is ready for starting with these critical checks. First, ensure your fuel valve is in the “ON” position—many riders forget this simple step after refueling. Next, check that your fuel line shows no cracks or kinks that could restrict flow to the carburetor. For cold starts, your fuel should contain the proper 2-stroke oil mixture at the manufacturer’s recommended ratio (typically 32:1 to 50:1 depending on your bike). If your bike has been sitting for weeks, drain old fuel and replace with fresh premix, as ethanol-blended fuels degrade quickly and cause starting issues.

Air Filter Inspection and Cleaning Protocol

A restricted air filter is the silent killer of easy starts on 2-stroke dirt bikes. Remove your air filter and hold it up to a light source— if you can’t see significant light passing through, it needs cleaning. For foam filters, wash with mild soap and water, then completely dry before re-oiling with proper air filter oil (never use motor oil). The filter should feel tacky but not dripping when correctly oiled. Reinstall the filter ensuring no gaps between the filter and air boot, as unfiltered air will destroy your 2-stroke engine rapidly.

Mastering the Correct Kickstarting Technique for 2-Stroke Engines

The physical act of kickstarting a 2-stroke dirt bike requires specific technique that differs significantly from 4-stroke models. Most riders unknowingly use improper form that reduces compression and prevents clean starts.

Positioning Your Body for Maximum Power Transfer

Stand on the left side of your bike with your left hand on the handlebar for stability. Place your right foot firmly on the kickstarter peg with the ball of your foot positioned at the very end of the lever. Bend your knees slightly and lean your upper body forward so your weight is centered over the bike. Your right knee should be slightly bent, ready to drive downward with force. This athletic stance allows you to use your entire body weight rather than just leg strength, which is crucial for overcoming compression on a cold 2-stroke.

The Two-Stroke Kick Sequence: Finding the Compression Point

2-stroke engines require a different kick technique than 4-strokes due to their simpler ignition timing. Begin by slowly kicking through the stroke to feel for the compression point—this is where you’ll feel significant resistance as the piston approaches top dead center. Once you identify this point (usually about 1/3 through the kick stroke), pull the kickstarter back slightly to reset, then deliver one firm, complete kick all the way through. Never “feather” the kickstarter or use short kicks, as this prevents the flywheel from reaching sufficient RPM for proper ignition. For cold starts, use full choke and kick with authority—2-strokes need that initial burst of RPM to fire properly.

Cold Start vs. Hot Start Procedures: Critical Differences

Many riders use the same starting procedure regardless of engine temperature, causing unnecessary wear and starting difficulties. Understanding these differences is essential for reliable starts.

Cold Start Protocol for Winter Riding Conditions

When temperatures drop below 50°F (10°C), your 2-stroke requires specific cold start procedures. Engage full choke and open the throttle 1/4 turn before kicking. Most modern 2-strokes have a decompression lever—use it to reduce the force needed during initial kicks. After 2-3 firm kicks, the engine should sputter to life. Immediately reduce choke to half and let the engine idle for 30-60 seconds to warm up. Never rev a cold 2-stroke immediately—this causes piston seizure from inadequate lubrication. The key is allowing time for the oil mixture to circulate properly before increasing RPM.

Hot Restart Method After Brief Riding Intervals

After riding for 10-15 minutes, your 2-stroke requires a completely different starting approach. Hot engines need less fuel and more air. Use no choke, crack the throttle slightly (about 1/8 turn), and kick with moderate force. Hot engines often start on the first kick if properly tuned. If your bike floods during hot starts (indicated by fuel smell and weak kicks), hold the throttle wide open and kick through several strokes to clear excess fuel. Never use full choke on a warm engine—this is the most common mistake riders make when restarting after a short break.

Troubleshooting Common 2-Stroke Kickstarting Failures

When your dirt bike refuses to start, systematic troubleshooting saves time and prevents further complications. These solutions address the most frequent starting issues riders encounter.

Why Your Kickstarter Feels Mushy With No Compression

If your kickstarter moves freely with little resistance, you’ve likely lost compression—a critical issue for 2-stroke operation. First, check your decompression lever position; if engaged, it will create this symptom intentionally. If the lever is disengaged, possible causes include a blown head gasket, broken piston rings, or bent valves (on reed valve models). Remove the spark plug and kick through—you should feel strong air pressure against your finger. No pressure indicates serious mechanical issues requiring professional attention before further starting attempts.

Diagnosing Flooding After Multiple Failed Kick Attempts

A flooded 2-stroke won’t start due to excess fuel drowning the spark plug. Symptoms include strong gasoline smell, dark soot on the spark plug, and kicks that feel unusually heavy. To clear a flood, remove the spark plug and kick through 5-6 strokes with throttle wide open to expel excess fuel. Dry the spark plug thoroughly or replace it, then restart with no choke and throttle fully open. Prevent future flooding by limiting choke usage to 2-3 kicks maximum and never holding the throttle open during initial kick attempts on a cold engine.

Essential Maintenance for Reliable Kickstarting Performance

Preventative maintenance is far easier than roadside repairs when your 2-stroke won’t start. These simple procedures ensure consistent starting performance season after season.

Carburetor Jetting Adjustments for Altitude Changes

As elevation changes, your carburetor requires jetting adjustments to maintain proper air-fuel mixture. At higher elevations (above 3,000 feet), decrease your main jet size by 2-4 numbers for every 1,000 feet gained. For cold weather starting, install a slightly larger pilot jet (2-4 numbers) to improve low-RPM fuel delivery. Always mark your original jetting configuration before making changes. Proper jetting ensures your 2-stroke receives the optimal fuel mixture for clean starts regardless of environmental conditions.

Spark Plug Selection and Gap Verification Process

Your spark plug choice significantly impacts starting performance. For most 2-strokes, use a hot plug (like NGK BR8ES) for cold weather and a colder plug (BR9ES) for summer riding. Check the gap with a wire gauge—most 2-strokes require 0.020-0.024 inches. A plug with improper gap or incorrect heat range causes weak sparks that fail to ignite the fuel mixture consistently. Replace plugs every 10-15 hours of riding time, as 2-strokes consume more oil which fouls plugs faster than 4-strokes.

Advanced Kickstarting Techniques for Problematic Starts

When standard procedures fail, these professional techniques can get your stubborn 2-stroke running when nothing else works.

The Bump Start Method for Dead Batteries or Weak Kickstarts

If your kickstarter lacks power or you’ve exhausted your leg strength, find a slight downhill slope. Position yourself on the bike with the transmission in second gear, clutch pulled in, and ignition on. Roll the bike to gain momentum (5-10 mph), then quickly release the clutch. The engine should fire from the rotational force. Immediately pull the clutch again to prevent stalling. This method works because the wheels driving the engine creates higher RPM than manual kicking, often overcoming compression issues that prevent normal starting.

Fuel Primer Technique for Extremely Cold Conditions

In freezing temperatures, standard choke procedures often fail. Add a few drops of fresh fuel directly into the carburetor throat (remove air filter to access), then kick with no choke. The direct fuel injection provides the richer mixture needed for cold starts without flooding from excessive choke use. Use extreme caution with this method—only 3-4 drops maximum, as too much fuel will flood the engine. This technique bypasses carburetor limitations in extreme cold but should only be used when standard methods fail.

Preventative Measures for Long-Term Starting Reliability

True starting reliability comes from proactive maintenance habits that keep your 2-stroke ready to fire up whenever you are.

Off-Season Storage Protocol to Prevent Starting Issues

Before storing your bike, run it with fuel stabilizer added to the tank until it coughs and dies—this ensures stabilized fuel throughout the system. Remove and clean the carburetor, spraying carb cleaner through all passages. Replace the spark plug with a new one pre-gapped correctly. Store with the fuel valve off and the float bowl drained. When you retrieve the bike, replace all fluids and the air filter—neglecting these steps guarantees difficult starts after storage.

Daily Pre-Ride Checks That Prevent Kickstarting Failures

Before every ride, perform these three critical checks: 1) Verify fuel flow by removing the float bowl drain screw (fuel should flow freely), 2) Check spark plug condition and gap, and 3) Ensure the air filter is properly seated with no gaps. These simple 60-second checks prevent 90% of starting failures. Many riders skip these basics then wonder why their bike won’t start when they’re ready to ride.

Final Note: Mastering how to kickstart a 2 stroke dirt bike transforms your riding experience from frustrating to fluid. By implementing these precise techniques and maintenance protocols, you’ll enjoy reliable starts regardless of conditions. Remember that consistent starting performance comes from understanding your bike’s specific needs—not brute force kicking. When in doubt, methodically work through the troubleshooting steps rather than repeatedly kicking a bike with an underlying issue. Proper starting technique preserves both your energy and your engine, ensuring more time riding and less time wrestling with a stubborn machine. Keep this guide handy until these procedures become second nature, and you’ll never again miss a single riding opportunity due to starting problems.