That smooth connection between your hand and the rear wheel disappears when your dirt bike clutch starts failing. When operating correctly, your clutch disengages seamlessly when you pull the lever, allowing smooth gear shifts without stalling. But when problems develop, you’ll notice subtle performance changes that quickly escalate to complete gear-shifting failure. Recognizing the early warning signs of a failing clutch saves you from costly repairs and prevents getting stranded mid-ride. This guide reveals the most common indicators that your dirt bike clutch needs immediate attention, helping you diagnose problems before they leave you pushing your bike home.

Recognize Clutch Slipping Symptoms

Clutch slipping delivers the most unmistakable sign that your clutch needs service. When you twist the throttle hard while in gear but the rear wheel doesn’t accelerate proportionally to engine RPM, you’ve got a slipping clutch. You might find yourself screaming through third gear while barely moving forward, or hear engine revs climb dramatically without matching speed increases. This happens because worn clutch plates can no longer maintain proper grip, allowing engine power to escape rather than transfer to the rear wheel.

Your clutch lever’s feel often changes dramatically during slippage. You might notice an unusually soft or vague response when pulling the lever, or experience a “grabby” sensation during engagement. Some riders describe the lever as feeling disconnected, making it difficult to find the proper engagement point. If you’re constantly adjusting the clutch cable trying to locate the bite point, internal wear—not just cable stretch—is likely the culprit.

Why Clutch Plates Slip

When operating correctly, your clutch’s drive plates and friction plates compress together during engagement, creating a solid connection between the clutch basket and inner hub. But as these plates wear from normal use, the friction material gradually thins through repeated engagement cycles. Eventually, the plates slip against each other instead of gripping firmly, breaking that critical power transfer link. This wear happens to every clutch, though aggressive riders who frequently slip the clutch during technical sections will experience faster deterioration.

Clutch springs also lose tension over time. These springs generate the clamping force that holds the pressure plate against the clutch pack, and when they weaken, they can no longer maintain sufficient pressure for positive engagement. Like the plates themselves, springs have a finite lifespan and will eventually require replacement. The combination of worn plates and tired springs creates perfect conditions for noticeable slippage during acceleration or hill climbing.

Fix Slipping Clutch Components

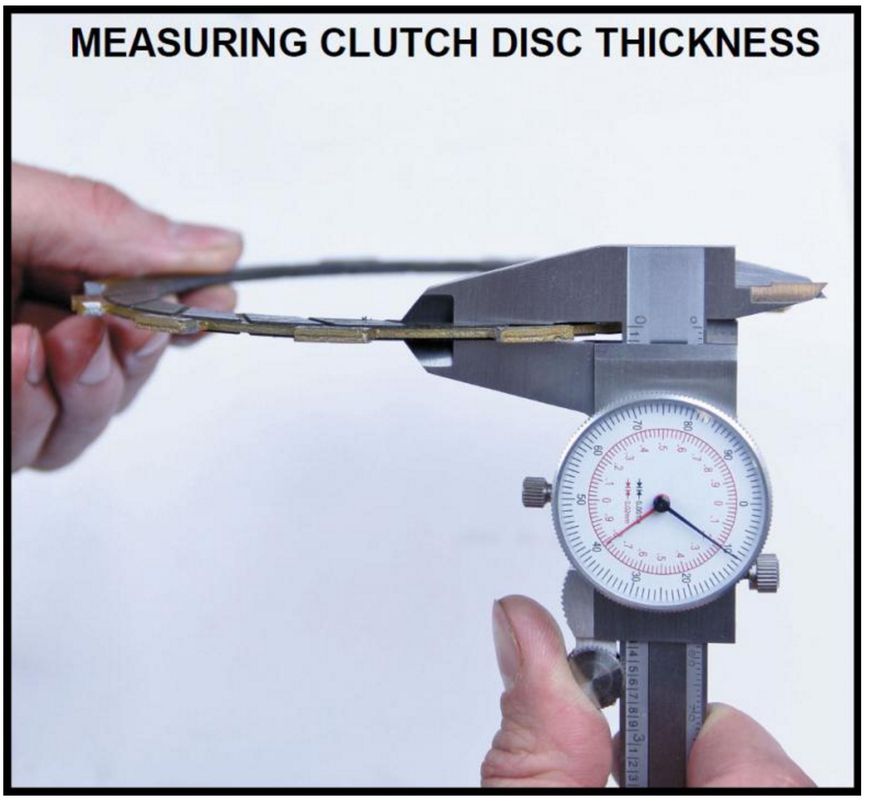

Addressing clutch slippage starts with measuring your clutch components. Remove the clutch cover—on most modern dirt bikes, you can simply lay the bike on its side and pop off the cover without major disassembly. Using a vernier caliper, measure the thickness of your steel drive plates and fiber friction plates, then compare these measurements to your owner’s manual specifications. Any plates below minimum thickness require replacement.

Next, measure your clutch springs’ free length with a ruler or caliper. Springs compressed beyond the minimum specification have lost their tension and need replacement. Aftermarket options from manufacturers like Wiseco meet or exceed OEM specifications at a lower cost and often include stiffer springs for more positive engagement. When installing new fiber plates, soak them in fresh motor oil for six to eight hours beforehand—this critical step ensures proper initial operation and smooth engagement.

Identify Burning Smell and Clutch Creeping

A pungent burning smell strong enough to “strip paint off a wall” signals serious clutch damage. This odor, often described as burnt toast or burnt paper, becomes particularly noticeable after removing the clutch cover or following heavy clutch usage. If you detect this smell while riding, your clutch has been generating excessive heat due to friction problems, and damage has already occurred to the friction material.

Clutch creeping provides another unmistakable warning sign. If your bike moves forward with the clutch lever fully pulled in and transmission in gear—no matter how much you adjust the cable—the clutch fails to fully disengage. This happens when warped or damaged plates prevent complete separation between the engine and transmission, causing unwanted power transfer that moves the bike when it should remain stationary.

Heat Damage Causes and Prevention

The burning smell results from clutch overheating caused by excessive friction between slipping plates. According to clutch experts, friction plates typically show damage first, developing a distinctive blackened appearance from heat exposure. You may also notice heat marks on the drive plates, indicating temperatures high enough to alter their surface properties. This heat damage cannot be reversed—once the friction material has been cooked, replacement is the only solution.

Preventing heat damage requires attention to riding habits and maintenance. Avoid “riding the clutch,” which means keeping the lever partially pulled in while stopped or moving slowly, as this causes constant friction and heat buildup. Follow manufacturer oil change recommendations, since many dirt bikes share oil between the clutch, transmission, and engine. Fresh oil provides proper lubrication and cooling, while degraded oil loses its protective properties and allows heat to build more quickly.

Replace Heat-Damaged Clutch Parts

When heat damage occurs, you cannot simply clean or repair the affected components—the damage is permanent. Inspect all plates for warpage by placing them on a flat surface and checking for gaps or rocking motion. Warped plates cause uneven engagement throughout the clutch’s operation range. Measure flatness specifications against your manual, and replace any components outside tolerance.

Beyond the plates, heat can also affect clutch spring tension, so measure spring free length and replace any springs that have compressed excessively. When replacing a heat-damaged clutch, consider investing in quality aftermarket components like forged clutch baskets, which offer superior resistance to impact and fatigue compared to stock cast aluminum parts. The denser material in forged baskets resists notching and damage from clutch plate engagement, providing longer service life.

Detect Abnormal Lever Feel and Dragging

The clutch lever serves as your primary interface with the clutch system, and changes in its feel often provide early warning of developing problems. A lever that feels lumpy, jerky, or catches unexpectedly during engagement indicates that the clutch basket and inner hub may be damaged. You might also notice the lever feeling unusually soft, requiring less effort to pull in than normal, or conversely, it may feel stiffer due to internal wear.

Grinding, squeaking, or rattling noises when operating the clutch provide additional warning signs that should not be ignored. A grinding or whining noise when pulling in the lever, combined with squeaking or clicking during gear changes, typically indicates that internal components like springs or plates have worn to the point of creating metal-on-metal contact. These sounds suggest advanced wear requiring immediate inspection.

Why Lever Feel Changes

Stock clutch baskets on most dirt bikes use diecast aluminum, which produces lightweight components but with significant material limitations. The casting process creates voids, porosity, and imperfections in the material structure, making the basket susceptible to damage over time. As clutch plates engage and disengage, they gradually create indentations in the basket tabs, preventing the plates from sliding smoothly across the engagement area. This irregular movement translates to the lumpy or jerky lever feel that riders experience.

The problem compounds when clutch plates cannot slide smoothly across damaged basket tabs. When you pull the lever to disengage, the plates should move freely across the basket width. Damaged tabs create resistance and irregular movement, making the lever feel inconsistent throughout its travel range. Riders often describe this as a “notchy” or “snagging” sensation that wasn’t present when the bike was new.

Billet and Forged Basket Upgrades

Upgrading to a superior clutch basket provides a long-term solution to lever feel problems caused by basket damage. Billet aluminum baskets offer improved density and strength compared to cast parts, as they are machined from compressed aluminum that undergoes additional processing to reduce porosity. However, forged baskets represent the highest quality option, produced by compressing aluminum under extreme pressure until all molecules bond tightly together.

Forged baskets feature “feature aligned grain flow,” where the material structure flows through the critical tangs and stanchions for dramatically improved strength. This manufacturing process enhances tensile strength, fatigue resistance, and ductility, meaning the basket can flex slightly under impact rather than cracking or notching. Many forged baskets receive hard coat anodizing and Teflon coatings that improve wear resistance and lubricity, further extending service life.

Watch for Additional Warning Signs

Beyond the primary symptoms, several additional indicators suggest clutch problems. Difficulty shifting gears often accompanies clutch wear, manifesting as gears that refuse to engage smoothly, grinding noises during shifts, or a stiff and unresponsive gear shift lever. If you find yourself forcing the transmission into gear or experiencing chronic grinding during transitions, your clutch plates may be worn or warped beyond acceptable limits.

Changes in clutch action provide subtle but important clues. Some riders notice that engagement happens almost when the lever is fully out, leaving almost no “play” in the lever before the clutch bites. This shortened engagement window indicates that the friction material has worn thin and the clutch requires attention. Four-stroke dirt bikes are particularly prone to heat-related changes that push the engagement point further out during aggressive riding.

Cable and Adjustment Limitations

Even after adjusting the clutch cable using the lever adjuster, if the clutch only engages right before you release the lever fully, internal wear is the likely cause rather than cable stretch. Clutch cables can stretch significantly over time, and many riders simply adjust the cable to compensate for wear without addressing the underlying problem. When performing clutch work, always replace the cable, as a new clutch requires proper cable adjustment to function correctly.

The adjustment process confuses many riders because the engagement point feels different with new components compared to worn ones. Take time to adjust the cable properly after installation, following manufacturer specifications for lever free play. Once adjusted correctly, the clutch should engage smoothly and predictably, with a clear “bite point” that you can feel consistently throughout the lever’s travel range.

Extend Clutch Lifespan

Proper maintenance and riding habits dramatically extend clutch service life. Avoid riding the clutch partially engaged during low-speed maneuvering or when stopped, as this constant slipping generates excessive heat and accelerates friction material wear. Use the friction zone judiciously during technical sections, engaging and disengaging cleanly rather than maintaining partial engagement for extended periods.

Regular oil changes according to manufacturer intervals keep the clutch properly lubricated and cool. Old oil breaks down from heat and friction, losing its protective properties and allowing wear to accelerate. Check clutch fluid levels if your system is hydraulic, and replace the fluid at recommended intervals. Periodically check cable tension and adjust as needed, addressing changes in lever feel before they develop into larger problems.

By learning to recognize the early warning signs of clutch wear and addressing problems promptly, you can avoid sudden clutch failure and extend the life of this critical component. The investment in regular inspection and timely replacement pays dividends in reliability and performance, ensuring your dirt bike is ready for every ride.