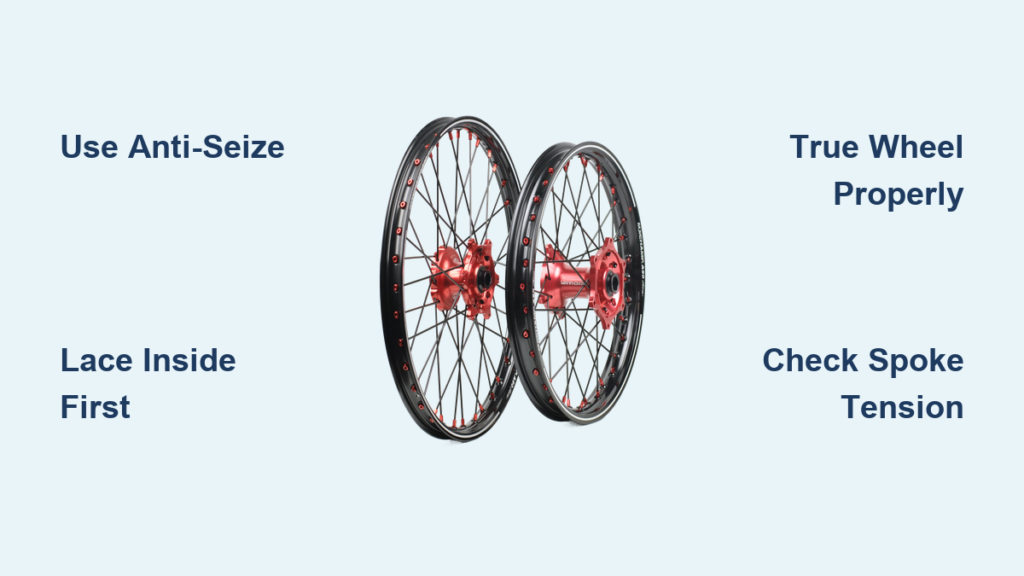

Ever found yourself staring at a pile of spokes, hub, and rim after a hard crash wondering how to rebuild your dirt bike wheel? Lacing dirt bike rims might seem like professional mechanic territory, but with the right approach, any rider can master this essential maintenance skill. Whether you’re restoring an older bike, replacing a damaged rim, or building a custom wheel combination that perfectly matches your riding style, understanding how to lace dirt bike rims opens up new possibilities for bike customization and performance. The process involves precisely arranging spokes between hub and rim, then methodically adjusting them until the wheel spins true and achieves correct tension for off-road durability. This guide walks you through the entire process with actionable steps that transform loose components into a rigid, reliable wheel assembly ready for the toughest trails.

Select Your Essential Wheel Building Tools

Before touching a single spoke, gather these critical tools to ensure professional results. A quality wheel truing stand is non-negotiable for accurate assessment of lateral wobble and radial hop – trying to true a wheel without one is like assembling furniture blindfolded. Spoke wrenches come in various sizes, so have multiple on hand since nipple dimensions vary between manufacturers. A torque spoke wrench proves invaluable during final tensioning, providing consistent pressure rather than relying on subjective feel.

Supplement these with digital calipers for precise measurements, a straightedge for checking offset, and an electric screwdriver with appropriate bits for initial nipple engagement. When removing old spokes, large bolt cutters or an angle grinder with a cutoff wheel dramatically speeds up the process. Safety glasses are mandatory when cutting spokes, as released tension can cause them to discharge unpredictably. An old blanket on your workbench protects anodized surfaces from scratches while keeping dropped components visible. Most importantly, apply anti-seize lubricant to spoke threads before installation – this dramatically improves tensioning accuracy and ensures future adjustments won’t be hindered by corrosion.

Why Anti-Seize Lubricant Makes or Breaks Your Build

Skipping anti-seize is the most common mistake first-time builders make. Without this critical step, friction during tensioning creates inconsistent torque readings, leading to uneven spoke tension that causes premature wheel failure. Apply a small amount to both the threaded portion of each spoke and the dimples in the rim where nipples seat. This simple step ensures the wheel can be easily retuned years later without fighting corroded components. Think of it as insurance against future maintenance headaches – the 30 seconds spent applying lubricant now could save you hours of frustration down the trail.

Document and Inspect Components Before Disassembly

Before removing a single spoke, photograph your wheel from multiple angles, capturing spoke orientation and hub-to-rim relationship. If working with a stock wheel, search online for images of the same make and model to verify correct spoke patterns. Factory service manuals provide invaluable specifications for offset measurements and tension values – worth obtaining for serious wheel work.

Examine components carefully before disassembly. Dirt bike wheels use two distinct spoke types: inside spokes with bends less than 90 degrees that install inside the hub flange, and outside spokes with bends exceeding 90 degrees that go outside the flange. On rear wheels with asymmetrical hubs, four variations exist – short inside, short outside, long inside, and long outside spokes. Witness marks on the hub from previous spokes clearly indicate which holes each spoke occupied and in what direction they were oriented, providing natural guidance for reconstruction.

Cut Old Spokes Efficiently for Maximum Time Savings

When replacing both spokes and nipples, cutting old spokes out rather than removing each nipple individually saves considerable time. Large bolt cutters handle this task effectively, capable of severing two spokes simultaneously when positioned properly. Leave the rubber rim strip in place during cutting to reduce the risk of discharged spokes, though safety glasses remain mandatory. An angle grinder with a cutoff wheel provides cleaner cuts but requires additional safety precautions including hearing protection.

For rim replacement while reusing original spokes, remove nipples while leaving spokes installed in the hub. This method dramatically reduces reassembly complexity by preserving correct spoke positions and eliminating individual reinstallation. After disassembly, thoroughly inspect the hub for damage that might not have been apparent while assembled, and clean all components of old threadlocker, corrosion, and debris before proceeding.

Install Inside Spokes First for Proper Foundation

The lacing process begins with inside spokes, establishing a stable foundation for subsequent outside spoke installation. Load the first inside spoke according to the hole shape in the hub flange – round holes require reference photographs while slotted holes naturally indicate correct orientation. Install all inside spokes into every other hole in both hub flanges, working from the outside of the flange inward.

Position the rim around the assembly using a blanket to prevent surface scratches. Each spoke naturally aligns with a specific rim hole based on its angle, making threading nipples straightforward. Thread nipple engagement requires only a few initial turns, as final tightening occurs after complete assembly. Work systematically around one side of the wheel at a time to ensure no positions are missed. Inside spokes typically install into every fourth hole in each rim side, maintaining consistent spacing throughout the pattern.

Complete Outside Spoke Lacing with Precision

After all inside spokes seat properly with engaged nipples, outside spoke installation begins. Work slowly, one-at-a-time, to minimize rim scratching against hub edges. Each outside spoke threads through the appropriate hub flange hole from the inside, going outward, then connects to the corresponding rim nipple. Maintain the same systematic approach used for inside spokes.

A properly loose-laced wheel exhibits even slack across all spokes, with the hub and rim remaining relatively movable. If one spoke group shows significant tension while others remain slack, the pattern has likely been established incorrectly. Verify your work by checking spoke crossings – symmetrical hub designs typically show spokes crossing two others, while asymmetrical designs often have one side crossing just one spoke and the opposite side crossing two or three.

True Your Wheel Accurately for Flawless Rotation

Mount the wheel in a truing stand with cones against the inner bearing race rather than rubber dust seals. Using the valve stem hole as a reference point standardizes all measurements. Initial nipple tightening proceeds evenly around the wheel, leaving approximately 0.125 to 0.25 inches of thread visible on each spoke.

Correcting lateral wobble requires loosening spokes on the side toward which the rim displaces while tightening spokes on the opposite side. Adjust two spokes on each side of the affected area for sufficient correction without creating new problems. For radial hop, tighten spokes on both sides of the affected area to draw the rim closer, or loosen to allow greater distance. Areas requiring correction typically involve four or more spokes to prevent stress concentrations.

Apply Final Tension to Match Dirt Bike Demands

Tensioning transforms the loosely assembled wheel into a rigid structure capable of withstanding off-road stresses. Continue systematic tightening while constantly checking for wobble and hop on each pass. Dirt bikes require higher tension than their weight suggests due to extreme off-road loads – typically 3.5 to 4.0 Newton-meters or 35 to 40 inch-pounds.

Experienced builders assess tension by sound, tapping spokes to listen for consistent pitch. Loose spokes produce low, dull sounds, while properly tensioned spokes emit clear, higher-pitched pings. Overtightened spokes risk cracking hub flanges or pulling nipples through the rim. The tap-for-tone technique requires practice, so listen to wheels known to be correctly built to develop this skill.

Complete Final Assembly with Proven Techniques

During final tensioning, shift emphasis from systematic tightening to fine adjustment by feel while maintaining the rim’s straight condition. Grind off any spoke protruding through the nipple to prevent puncturing the inner tube. Install a new rubber rim strip to protect the tube from spoke ends and nipple shoulders.

The finished wheel should spin freely without visible wobble or hop, with all spokes showing similar tension. After installing the tire and tube, check the wheel for true after the first ride, as component settlement can occasionally cause minor tension changes. The zip-tie method provides safety for complex rebuilds – zip-tying all spokes together at crossing points after removing the old rim keeps the entire assembly in correct pattern during reassembly.

Prevent Common Lacing Mistakes That Cause Wheel Failure

First-time builders often make these critical errors: skipping anti-seize lubrication, rushing the truing process, applying inconsistent tension, and ignoring spoke sound during final tensioning. The most catastrophic mistake is overtightening spokes on one side to correct wobble without balancing tension on the opposite side, creating stress concentrations that lead to premature failure.

Take breaks when frustration builds – wheel building requires patience more than mechanical genius. A first-time build may take several hours, but this investment yields both cost savings and the satisfaction of completing a precision mechanical task. Most builders find the experience rewarding enough to seek additional wheel projects after their first successful build. With practice, completing a wheel becomes a manageable one-hour task, opening doors to custom builds that perfectly match your riding style and trail conditions.