You’ve turned the key, kicked the starter, and given it everything you’ve got—yet your 2-stroke dirt bike refuses to fire up. That frustrating “hard to start” problem is one of the most common headaches for off-road riders, especially when you’re ready to hit the trails and time is wasting. Unlike 4-stroke engines that often start with minimal fuss, 2-stroke dirt bikes require precise conditions to ignite properly, and when something’s off, they’ll let you know with stubborn silence. Whether you’re dealing with a cold morning struggle or a bike that suddenly won’t start after running fine, understanding the specific reasons behind your 2-stroke dirt bike hard to start problem is the first step to getting back on the track.

Most starting issues with 2-stroke dirt bikes fall into three critical categories: fuel delivery problems, ignition system failures, or compression issues. The beauty of 2-stroke engines is their relative simplicity compared to 4-strokes, but this simplicity means each component must function perfectly for successful starting. What makes diagnosis tricky is that multiple systems work together—your bike might have adequate spark and fuel but still refuse to start due to a subtle air leak or worn reed valve. In this guide, you’ll learn exactly which components to check in the right order, saving you hours of guesswork and unnecessary part replacements.

Spark Plug and Ignition System Failures That Prevent Starting

How to Test Your 2-Stroke Dirt Bike’s Spark Properly

The first thing to check when your 2-stroke dirt bike hard to start problem appears is the spark system—specifically whether you’re getting a strong, blue spark at the plug. Many riders make the mistake of just looking at the plug without properly testing the entire ignition chain. To correctly check for spark, remove the spark plug while keeping it connected to the spark plug cap, then ground the metal base against the cylinder head. Have someone kick over the engine while you watch for a visible spark jumping the gap. Important: Never hold the plug by the ceramic insulator—use insulated pliers to avoid shock.

If you see no spark or only a weak yellow spark, work backward through the system: check the spark plug cap for cracks, examine the spark plug wire for damage, and verify connections at the CDI (Capacitor Discharge Ignition) unit. A common but often overlooked issue is a faulty kill switch—disconnect the kill switch wiring entirely to rule this out as the culprit. Many modern 2-strokes have safety features that prevent starting if the transmission is in gear, so ensure your bike is in neutral with the clutch pulled.

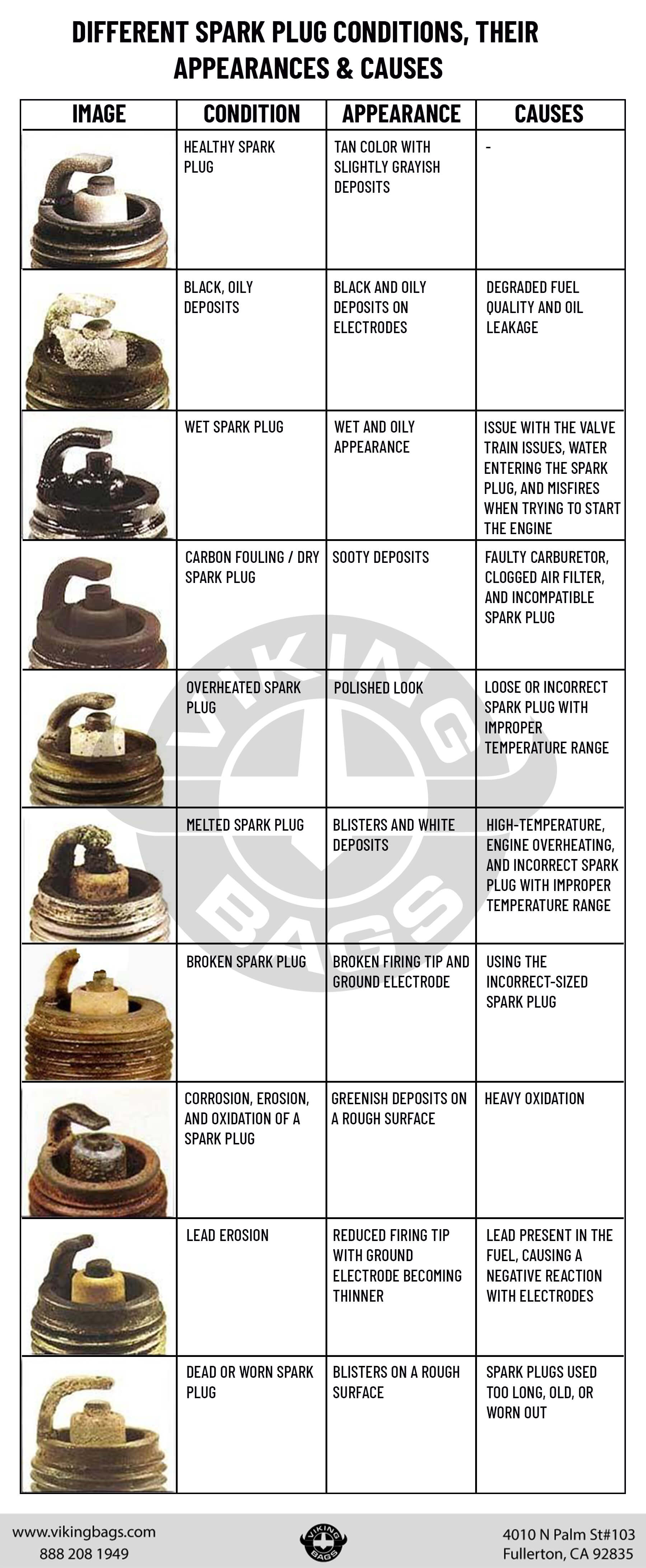

Why Your Spark Plug Might Be Fouled (And How to Fix It)

A fouled spark plug is one of the most frequent reasons for a 2-stroke dirt bike hard to start condition, especially after multiple failed starting attempts. Unlike 4-strokes, 2-strokes burn oil mixed with fuel, which can quickly coat the plug electrodes when the engine doesn’t fire properly. Remove your spark plug and inspect it—black, wet deposits indicate rich fuel mixture or flooding, while white or blistered electrodes suggest overheating.

Pro tip: Keep a clean spare plug at the track for quick testing—swapping in a known-good plug takes seconds and immediately tells you if your original plug is the problem. When cleaning a fouled plug, use a wire brush (never sandpaper, which can leave conductive residue) and carefully check the gap with a feeler gauge. For persistent fouling issues, consider stepping up to a hotter heat range plug that better matches your riding conditions.

Fuel Delivery Problems That Stop Your 2-Stroke from Starting

Diagnosing Carburetor Issues Step-by-Step

When your 2-stroke dirt bike hard to start problem appears suddenly after running fine, the carburetor is often the culprit. Stale fuel is public enemy number one for 2-stroke carburetors—ethanol-blended gasoline breaks down quickly, leaving varnish that clogs tiny fuel passages. Before tearing apart your carb, try this quick test: with the air filter removed, give two quick shots of starting fluid into the intake while kicking over the engine. If the bike fires but doesn’t stay running, you’ve confirmed a fuel delivery problem.

Critical check: Remove and inspect your float bowl—many starting issues stem from a stuck float needle or debris in the bowl. Pay special attention to the pilot jet (responsible for low-RPM fuel delivery), which is extremely small and easily clogged. Use carburetor cleaner and compressed air to clear passages, but never use wire or metal objects that can damage the precisely sized orifices. If you’ve recently cleaned your carb and still have starting issues, double-check that all gaskets are properly seated—air leaks around the carburetor can lean out your mixture enough to prevent starting.

How to Identify Air Leaks That Prevent Proper Starting

Air leaks are silent killers for 2-stroke starting performance, often causing those frustrating “hard to start” symptoms that come and go mysteriously. These leaks create an unintended air-fuel mixture that’s too lean to ignite properly, especially when the engine is cold. To check for air leaks, spray carburetor cleaner around potential leak points (intake boot, carburetor mounting flange, crankcase seals) while the engine is running. If the RPM changes when you spray a particular area, you’ve found your leak.

Common leak locations:

– Cracked or deteriorated intake boot between carb and cylinder

– Loose carburetor mounting bolts

– Worn crankshaft seals (particularly the right-side seal on kick-start models)

– Cracked reed valve housing

Fixing air leaks often requires replacing rubber components or resealing connections—don’t waste time trying to “seal” leaks with tape or makeshift solutions that will fail under heat and vibration.

Compression and Mechanical Issues That Block Starting

Simple Compression Test Methods for Trailside Diagnosis

Low compression is a less common but serious cause of 2-stroke dirt bike hard to start problems. Unlike 4-strokes, 2-strokes rely entirely on case compression to draw in the fuel-air mixture, so any loss of seal integrity affects starting dramatically. You don’t need special tools for a basic compression check—simply remove the spark plug, cover the hole with your thumb, and kick through the stroke. You should feel significant resistance on the compression stroke.

For a more accurate measurement, use a compression gauge designed for 2-strokes (they typically read lower than 4-stroke gauges). Most 2-stroke dirt bikes need at least 90-110 PSI for reliable starting, though specifications vary by model and displacement. Warning: Extremely low compression (below 70 PSI) usually indicates serious mechanical issues like worn piston rings or damaged cylinder ports that require professional attention.

Reed Valve Inspection Without Complete Engine Disassembly

The reed valve is the heart of your 2-stroke’s intake system, and when it fails, starting becomes difficult or impossible. Fortunately, you can often inspect reeds without splitting the cases—many dirt bikes have reed valve access plates on the side of the engine. Remove this cover and examine the reed petals for cracks, chips, or warping. Gently press on each petal—if it doesn’t seal completely against the reed block or feels stiff, replacement is needed.

Pro tip: Carry spare reed petals in your trail kit—replacing just the damaged petals takes minutes and gets you back riding. When installing new reeds, apply a tiny drop of two-stroke oil to the hinge points to prevent immediate sticking. Pay attention to reed orientation during installation—most have a “front” and “back” that affects airflow direction.

Quick Fixes and Prevention Strategies for Reliable Starting

Cold Weather Starting Techniques That Actually Work

Cold mornings transform even well-tuned 2-strokes into hard-to-start nightmares. The solution isn’t just more choke—it’s understanding how temperature affects your fuel mixture. When temperatures drop below 50°F (10°C), your standard jetting becomes too lean because cold air is denser. Install a winter needle jet if your carb supports it, or temporarily richen your mixture by raising the needle clip position one notch.

The perfect cold-start sequence:

1. Set choke fully on

2. Pull throttle slightly (1/8 turn)

3. Kick through 3-4 compression strokes without spark plug

4. Install plug and kick with normal effort

5. As soon as it fires, back off choke gradually

Never hold full throttle while starting—that floods the engine and washes oil from cylinder walls, causing premature wear.

Essential Maintenance Habits to Prevent Starting Problems

The best solution for 2-stroke dirt bike hard to start issues is prevention through proper maintenance. After every ride, run the engine until it’s nearly out of fuel to prevent stale gas from gumming up your carburetor overnight. Change your air filter regularly—dirt in the intake system affects your air-fuel ratio dramatically. And most importantly, use fresh, high-octane fuel with a quality 2-stroke specific oil at the correct ratio (typically 32:1 to 50:1 depending on your model).

Critical monthly checks:

– Inspect spark plug condition and gap

– Clean carburetor pilot circuit

– Check reed valve for damage

– Verify proper choke operation

– Examine all fuel lines for cracks

If you follow these maintenance habits consistently, you’ll spend less time troubleshooting and more time riding—because the best fix for a hard-starting 2-stroke is making sure it never becomes hard to start in the first place.