Your 4 stroke dirt bike refuses to fire up right when you’re ready for an epic ride. You’ve checked the basics, but that stubborn engine just won’t turn over. Whether you’re stranded at the trailhead or frustrated in your garage, this guide delivers the precise diagnostic steps you need to get your dirt bike running again—without wasting time on unnecessary part replacements.

Most 4 stroke dirt bike starting problems fall into four main categories: fuel system failures, ignition issues, compression problems, or electrical faults. By following this systematic approach, you’ll eliminate guesswork and pinpoint the exact cause of your starting failure. In the next few minutes, you’ll learn how to methodically check each system, identify the specific failure point, and apply the correct fix—saving you hours of frustration and potentially hundreds in unnecessary repairs.

Fuel System Failures That Prevent Starting

How to Diagnose a Clogged Fuel Line or Filter

Your dirt bike’s fuel system requires unobstructed flow from tank to combustion chamber. Start by visually inspecting the fuel line for kinks or cracks that restrict flow. Remove the fuel line from the carburetor or fuel injection rail and place it in a container while turning the fuel valve to “ON.” Healthy fuel flow should produce a steady stream—not just drips. If flow is weak, disconnect the line at the tank end and check for debris. A clogged inline fuel filter often causes intermittent starting problems that worsen over time.

Carburetor Jet Blockage Troubleshooting

A partially blocked main jet creates lean running conditions that prevent cold starts. Remove the float bowl and inspect the main jet using a bright light. Look for varnish deposits or debris obstructing the tiny opening. Never use a wire to clear jets—this alters critical dimensions. Instead, soak the jet in carburetor cleaner for 15 minutes, then blow through it with compressed air. Reinstall and test. If your bike starts but dies immediately, the pilot jet likely needs similar cleaning.

Ignition System Failures That Stop Your Engine

Spark Plug Diagnosis: Beyond Just Checking for Spark

Don’t just look for a spark—evaluate its quality. Remove your spark plug and reconnect it to the boot while grounding the base against the cylinder head. Crank the engine and observe: a healthy spark appears bright blue and snaps sharply, while a weak spark looks orange and feeble. Check your spark plug gap with a feeler gauge—most 4 stroke dirt bikes require 0.028-0.032 inches. A fouled plug with black, wet deposits indicates rich fuel mixture, while white deposits suggest overheating.

CDI Unit and Stator Testing Without Special Tools

Your CDI (Capacitor Discharge Ignition) unit can fail partially, allowing spark at high RPM but not during starting. Test your stator’s charging coil output with a multimeter set to AC volts. Disconnect the stator plug and measure between the two white wires while cranking—the reading should exceed 50V AC. Low voltage indicates stator failure. Check all ignition system connections for corrosion, especially at the kill switch wiring, which commonly fails from moisture exposure.

Compression Problems That Hinder Starting

Quick Field Test for Adequate Compression

You don’t need a gauge to verify basic compression. Remove the spark plug and cover the hole with your thumb while kicking over the engine. Proper compression should firmly push your thumb off the hole with noticeable resistance. If you feel weak pressure, suspect worn piston rings or valve issues. Listen for air escaping through the carburetor (intake valve problem) or exhaust pipe (exhaust valve issue) during your kickstart attempts.

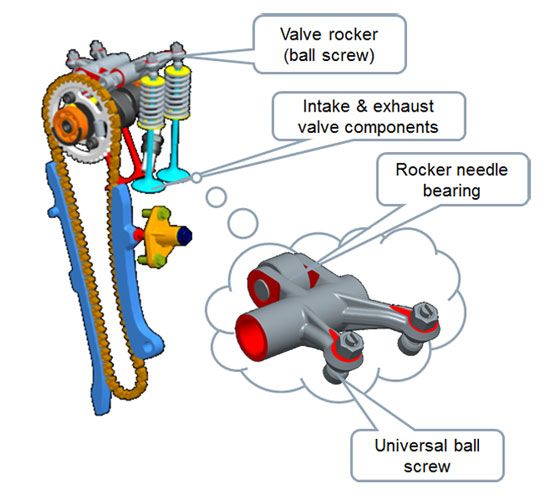

Valve Clearance Checks That Prevent Starting

Incorrect valve clearance is a common culprit in hard-starting 4 strokes. When valves don’t seal properly, compression leaks prevent ignition. Check valve clearances when the engine is cold using feeler gauges. Intake valves typically need 0.004-0.006 inches clearance, exhaust valves 0.006-0.008 inches. If clearance is too tight (or zero), valves won’t fully close. If your bike ran fine then suddenly wouldn’t restart after overheating, bent valves could be the issue.

Electrical System Failures That Stop Everything

Identifying Battery Drain Before Replacing Components

A weak battery often masquerades as other problems. Test your battery voltage before and during cranking—healthy voltage should stay above 11.5V while cranking. If voltage drops below 10V, your battery can’t deliver sufficient power to the fuel pump and ignition system. Clean all battery terminals and ground connections, as corrosion creates resistance that starves electrical components. Check for parasitic drain by connecting an ammeter between the negative battery terminal and cable—more than 20mA drain indicates a wiring fault.

Starter Motor Engagement Issues Specific to Dirt Bikes

Unlike street bikes, dirt bikes experience more starter gear damage from mud and impacts. If you hear a single “clunk” without cranking, the starter drive gear may be stripped. Remove the starter motor and inspect the Bendix drive mechanism for worn teeth. While starter motors fail less frequently than fuel or ignition issues, mud contamination can cause binding that prevents proper engagement with the engine’s ring gear.

Common Mistakes That Worsen Starting Problems

Why Flooding Your Engine Makes Starting Impossible

Riders often hold the throttle wide open when starting a reluctant 4 stroke, but this floods fuel-injected models and richens carbureted models beyond ignition capability. For carbureted bikes, use the choke properly—full choke for cold starts, then gradually reduce as it warms. Fuel-injected bikes automatically adjust, so hold the throttle completely closed. If flooded, hold the throttle wide open while cranking to clear excess fuel.

Improper Kickstart Technique That Prevents Compression

Most riders kick too slowly through the compression stroke. Position your foot at the top of the kickstart lever’s travel, then deliver a fast, forceful kick that snaps through the compression point. A slow kick allows compression to build gradually, reducing the energy transferred to the engine. This technique difference often determines whether a marginal compression engine will start.

Preventative Maintenance That Avoids Starting Failures

Fuel System Preservation for Infrequent Riders

Ethanol-blended fuel degrades quickly, causing varnish that clogs jets within weeks. Add fuel stabilizer to every tank and run the engine for 5 minutes to circulate it through the system. For bikes stored longer than 30 days, either drain the float bowl completely or use ethanol-free fuel with stabilizer. Replace rubber fuel lines every two years—they absorb ethanol and shed particles into your system.

Electrical Connection Protection Against Trail Conditions

Seal all electrical connectors with dielectric grease before rides to prevent moisture intrusion. Pay special attention to the CDI unit connections and stator plug, which commonly fail from water exposure. Routinely check wire routing to ensure no chafing against frame components, especially near suspension pivot points where movement occurs.

Final Note: When your 4 stroke dirt bike won’t start, systematic diagnosis beats random part replacement every time. By methodically checking fuel delivery, ignition quality, compression integrity, and electrical health in that order, you’ll solve 95% of starting issues without specialized tools. Remember that most starting problems originate in the fuel or ignition systems—always verify spark and fuel flow before dismantling your top end. Keep basic tools and spare spark plugs in your riding gear, and perform the preventative maintenance steps outlined here to minimize roadside troubleshooting. With these diagnostic skills, you’ll spend less time pushing your bike back to the truck and more time enjoying the trails.