That high-pitched squeal from your dirt bike brakes can turn an exhilarating trail ride into a frustrating experience. When your dirt bike brakes squeaking interrupts your flow on the trail, it’s not just annoying—it often signals underlying issues that could compromise your braking performance. This common problem affects riders from weekend warriors to professional GNCC racers, especially in muddy, sandy, or dusty off-road conditions where brake systems face extreme demands. The good news is that most brake squeaking stems from identifiable causes that you can fix with basic maintenance knowledge and the right techniques.

Brake squeaking occurs when vibration transfers from the brake pads to the rotor at specific frequencies, creating that distinctive high-pitched sound. Manufacturers design brake systems with shims and dampening materials to suppress these vibrations, but the harsh reality of off-road riding—mud, sand, water, and intense heat—often overwhelms these solutions. Understanding why your dirt bike brakes squeaking happens is the first step toward silencing that noise and restoring confident braking performance. Whether you ride a KTM, Yamaha, Honda, or other brand, these fixes apply universally to solve your squeaking problem.

Why Your Dirt Bike Brakes Squeak During Trail Rides

The Physics of Brake Vibration Transfer

When your dirt bike brakes squeaking starts, it’s usually due to pad oscillation at frequencies between 500-5,000 hertz—the exact range where human hearing is most sensitive. This vibration occurs because brake pad pressure isn’t perfectly uniform across the entire surface. Tiny variations in pad material density, rotor flatness, and caliper alignment cause friction coefficient fluctuations as the rotor spins. Harder pad materials vibrate more intensely than softer compounds, while thinner rotors flex more easily, amplifying the squeak.

Professional racers experience brake squeaking more frequently not because they have special equipment, but because they push their brakes harder and longer. This intense usage generates enormous heat through constant modulation, accelerating wear and vibration. Most weekend riders actually encounter less squeaking because their riding style creates different thermal patterns in the brake system.

How Riding Style Affects Brake Noise

Your braking technique directly impacts whether your dirt bike brakes squeaking develops. Riders who drag their rear brake for stability during cornering often experience more squeaking than those who modulate braking more aggressively. The constant light pressure creates ideal conditions for vibration to build up at resonant frequencies. Similarly, riders who frequently ride in muddy conditions may notice their brakes stay quieter during wet rides but develop squeaking once components dry out.

Pay attention to when the squeaking occurs—immediately after water exposure, during hard braking, or only at low speeds. This pattern helps identify the specific cause. For example, squeaking that appears only after extended hard riding typically indicates heat-related vibration, while noise that happens only when wet suggests contamination issues.

Hard Brake Pads Causing KTM and Other Dirt Bike Squeaking

Choosing the Right Pad Compound for Quiet Operation

KTM motorcycles have earned a reputation for particularly squeaky brakes, primarily due to the harder factory-installed pads designed for exceptional wear resistance. While these hard pads withstand aggressive off-road riding, their composition makes them more prone to vibration. If your dirt bike brakes squeaking started after installing new pads, the pad compound is likely the culprit.

Softer compounds generally operate more quietly but wear faster, while harder compounds last longer but tend to squeak more. For most recreational riders, mid-range options like EBC MX-C pads provide the best balance—decent longevity without excessive noise. Premium Brembo pads work well for endurance racers but often squeak more for casual trail riders. When replacing pads, consider switching to a compound with less metallic content for quieter operation.

Fixing Glazed and Worn Brake Pads

Worn pads often develop uneven wear patterns that cause squeaking, especially when brake pins develop wear over time. This prevents proper pad movement, causing misalignment and vibration. Similarly, dried-out caliper slide pins create uneven pad wear between inner and outer pads, leading to inconsistent contact.

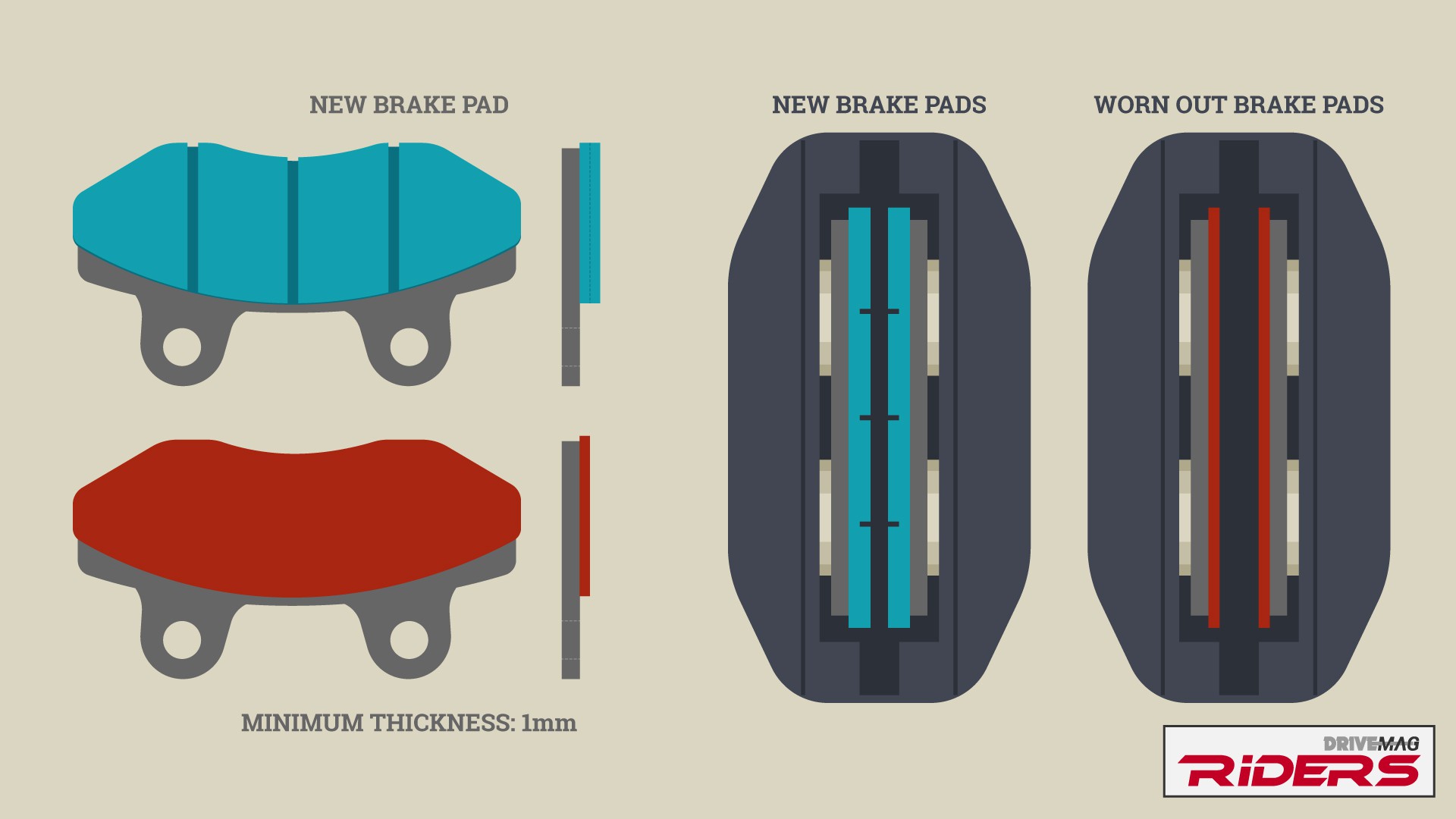

Glazing occurs when brake pads overheat, creating a shiny, hard surface that reduces braking efficiency while increasing noise. Glazed pads often appear polished and may have hard spots that feel smooth to the touch. Light sanding can sometimes restore glazed pads, but severe cases require replacement. If you notice your dirt bike brakes squeaking mostly at low speeds, check for the wear pattern where the inside of the pad contacts only the outer edge of the rotor—a common sizing issue with non-OEM components.

Bent Rotor and Caliper Alignment Issues Creating Squeaks

Straightening Bent Rotors and Caliper Realignment

Bent rotors are a frequent cause of dirt bike brakes squeaking that many riders overlook. Rotors can bend from impacts with debris, improper installation, or excessive heat cycling. A bent rotor creates uneven contact with the pads, generating vibration with every rotation. Most bent rotors can be straightened using an adjustable spanner by spinning the wheel and observing the rotor through the caliper to identify the bend location.

Caliper alignment is equally critical. Loosen the caliper mounting bolts, apply the brake to center the caliper over the rotor, then retighten the bolts while holding the brake applied. This simple alignment procedure often eliminates squeaking caused by caliper drift. Pay special attention to rear calipers that slide on cast aluminum channels—they require proper lubrication to maintain smooth movement and even pad contact.

Floating Rotor Noise Considerations

While floating rotors work well for heat dissipation on front brakes, they’re particularly prone to squeaking and rarely used on rear brake applications. The floating design allows expansion with heat but creates inconsistent pad contact that generates noise. Some aftermarket rotors like TUSK models are known for significant squeaking despite good stopping power—highlighting the trade-offs in component selection.

Before replacing your rotor, ensure the problem isn’t simply contamination or misalignment. Many riders mistakenly replace perfectly good rotors when simple cleaning or adjustment would have solved their dirt bike brakes squeaking issue.

Proper Lubrication Techniques to Silence Squeaky Brakes

Critical Lubrication Points for Noise Reduction

The backs of brake pads should be lubricated where they contact the caliper piston using copper grease or red silicone brake lubricant. This prevents vibration transfer to the caliper body, significantly reducing noise. However, never get lubricant on the friction surfaces—even a tiny amount dramatically reduces braking power and creates dangerous conditions.

Slide pins require high-temperature silicone grease to ensure smooth caliper movement. Apply grease to all moving surfaces, including pad protrusions that sit in caliper notches. The rear caliper typically has only one sliding pin, with the other side featuring a protrusion that sits in a notch—both surfaces need proper lubrication. Anti-seize compounds work well on pad backs but must be reapplied carefully after piston reinsertion.

Common Lubrication Mistakes That Worsen Squeaking

The most dangerous lubrication mistake is contaminating friction surfaces. When applying grease, use precision applicators and wipe away excess immediately. Inspect rotors after installation to confirm they’re clean. Another common error involves using standard grease instead of high-temperature silicone—regular grease liquefies when hot and migrates to friction surfaces.

Using too much lubricant on slide pins attracts dirt and debris, creating an abrasive paste that accelerates wear. Apply just enough to coat moving surfaces without excess. Remember that proper lubrication isn’t about eliminating all movement—it’s about ensuring smooth, controlled movement that prevents vibration transfer.

Step-by-Step Cleaning Process for Noisy Dirt Bike Brakes

Effective Cleaning Methods for Contaminated Components

Start by removing visible debris from pads and rotors using a clean rag. For disc brakes, clean rotors with oil-free degreaser or dedicated disc brake cleaner—never use products that leave residue. Contaminated pads may require removal for thorough cleaning; light sanding often restores proper friction surfaces. In severe cases, pads may need replacement or burning clean with a blowtorch.

A surprisingly effective method involves creating a lather with dish washing liquid and the pads to remove stubborn contamination. After cleaning, rinse thoroughly and allow components to dry completely before reassembly. This simple process has resolved squeaking for riders who tried other approaches without success.

Preventing Future Contamination

After cleaning, inspect for potential contamination sources. Chain lubricant often sprays onto rear brakes during riding—adjust your lube technique to minimize overspray. Keep spray lubricants away from brake components when maintaining other bike parts. Regular cleaning prevents the accumulation of abrasive particles that accelerate wear and create noise.

When to Replace Parts to Eliminate Persistent Squeaking

Pad Replacement Guidelines for Noise-Free Braking

Replace pads before they reach minimum thickness—worn pads develop wear patterns that cause squeaking and can damage rotors. If squeaking started after pad replacement, try a different compound with less metallic content. Softer pads generally operate more quietly but wear faster, while harder compounds last longer but tend to squeak more.

Pay attention to specific wear patterns. If the inside of the pad contacts only the outer edge of the rotor, you likely have a sizing issue with non-OEM components. Either use properly matched parts or adjust caliper positioning for even contact across the rotor surface.

Fluid Changes and Hardware Replacement

Change brake fluid regularly—contaminated fluid causes brake drag that generates heat and noise. Overheated fluid breaks down, reducing braking performance while exacerbating squeaking. Replace worn slide pins and hardware promptly; the small cost prevents uneven pad wear and maintains proper function.

Consider rotor replacement if cleaning, adjustment, and pad changes fail to resolve squeaking. Severely bent or worn rotors often require replacement rather than repair. When replacing rotors, choose designs known for quiet operation if noise is your primary concern.

Preventing Brake Squeak with Proper Bed-In Procedures

Bedding-In New Components for Quiet Performance

New pads and rotors require proper bed-in to achieve optimal performance and noise characteristics. Ride at moderate speed and apply brakes firmly enough to slow without stopping completely. Repeat several times, allowing cooling between applications. Complete this process over multiple rides rather than all at once—excessive heat during initial bed-in can glaze pads and create noise issues.

During bed-in, new pads may squeak more than they will after conditioning. This is normal and shouldn’t concern you unless noise persists beyond several rides. If squeaking continues after proper bed-in, investigate other causes like contamination or misalignment.

Establishing a Maintenance Routine

Before each ride, perform a quick visual inspection of brake components. Check pad thickness, look for uneven wear patterns, and ensure all mounting hardware is secure. Measure pad thickness regularly using a caliper and plan replacements before pads reach minimum specifications.

Keep a log of pad wear rates to predict replacement intervals. This simple habit prevents noise and performance issues while ensuring your dirt bike brakes operate quietly and effectively for seasons of trail riding ahead. Regular maintenance beats emergency fixes when you’re miles from the trailhead with squeaky brakes.