That frustrating moment when your screwdriver slips and ruins your dirt bike’s fuel bowl drain screw during routine maintenance is all too familiar for Yamaha, Suzuki, and Kawasaki owners. Dirt bike fuel bowl drain screw stripping happens frequently because manufacturers use soft brass or aluminum JIS (Japanese Industrial Standard) screws that look like Phillips heads but require specialized tools. When these vulnerable screws strip, you’re left stranded during critical maintenance like winter storage or carburetor cleaning. This guide delivers proven extraction techniques and prevention strategies that get you back on the trail fast—no dealership visits required.

Why Your Fuel Bowl Drain Screw Strips Every Time

The root cause of dirt bike fuel bowl drain screw stripping lies in the deceptive similarity between JIS and Phillips fasteners. Your standard Phillips screwdriver appears to fit but actually cam outs under pressure because JIS screws have a shallower cross-slot with a blunter driver profile. This critical difference means your Phillips driver only partially engages the screw head, causing immediate damage to the soft brass or aluminum construction.

JIS vs. Phillips: The Hidden Design Trap

Spot the difference: JIS screws often feature a single dot on one side of the head, but this marking isn’t always visible. The matching JIS screwdriver has a tip that fully engages the shoulder of the fastener, while your standard Phillips driver’s pointed tip only contacts the middle cavity. This fundamental mismatch causes catastrophic stripping within seconds as the driver slips under torque, destroying the soft metal head. Even experienced mechanics get fooled—the visual similarity makes this the most common preventable maintenance mistake on Japanese dirt bikes.

Soft Metal as a “Torque Fuse” Backfires

Manufacturers intentionally use soft brass or aluminum for drain screws to protect your expensive carburetor body—these screws act as a sacrificial “torque fuse” that strips before damaging critical components. While this design philosophy saves your carburetor from catastrophic damage, it makes the drain screw itself extremely vulnerable. The very feature meant to protect your investment becomes your biggest frustration during routine maintenance. Once corrosion sets in during storage, the combination of oxidized threads and soft metal creates perfect stripping conditions.

Three Critical Stripping Scenarios to Avoid

Winterization attempts cause most dirt bike fuel bowl drain screw stripping incidents—riders discover their screw has seized after months of fuel residue buildup. Carburetor cleaning preparations follow closely, as removing the drain screw is essential before float bowl extraction. Finally, emergency post-water crossing drainage often fails when riders try to remove a seized screw in the field. Bikes stored longer than 90 days face exponentially higher stripping risk due to corrosion bonding the threads to the carburetor body.

Stop Stripping: Essential Prevention Tools You Need Now

Preventing dirt bike fuel bowl drain screw stripping requires just two critical investments that pay off every maintenance session. These simple solutions eliminate the frustration of ruined screws and stranded rides.

Get the Right JIS Screwdriver (Not Phillips!)

Your Yamaha factory toolkit likely contains the correct JIS #2 driver—check under the right side panel before buying new tools. For standalone purchases, Motion Pro’s T-handle JIS set ($22) or individual bits ($3.50 each) provide perfect engagement. Amazon now carries multiple JIS options specifically labeled for motorcycle use—search “JIS #2 motorcycle screwdriver” to avoid counterfeits. Never use standard Phillips drivers on these screws—they guarantee stripping every time.

Master the Proper Removal Technique

Always wiggle your JIS driver while applying firm downward pressure to fully seat the tip before turning. Crucially, turn clockwise first to break the corrosion bond before attempting counterclockwise removal—this preserves the screw’s integrity. For stubborn screws, dip your driver tip in valve grinding compound for extra grip and use a 12-inch shank driver for maximum leverage. Pro tip: Apply gentle clockwise pressure while tapping the driver handle with a hammer—this often breaks the bond without damaging the head.

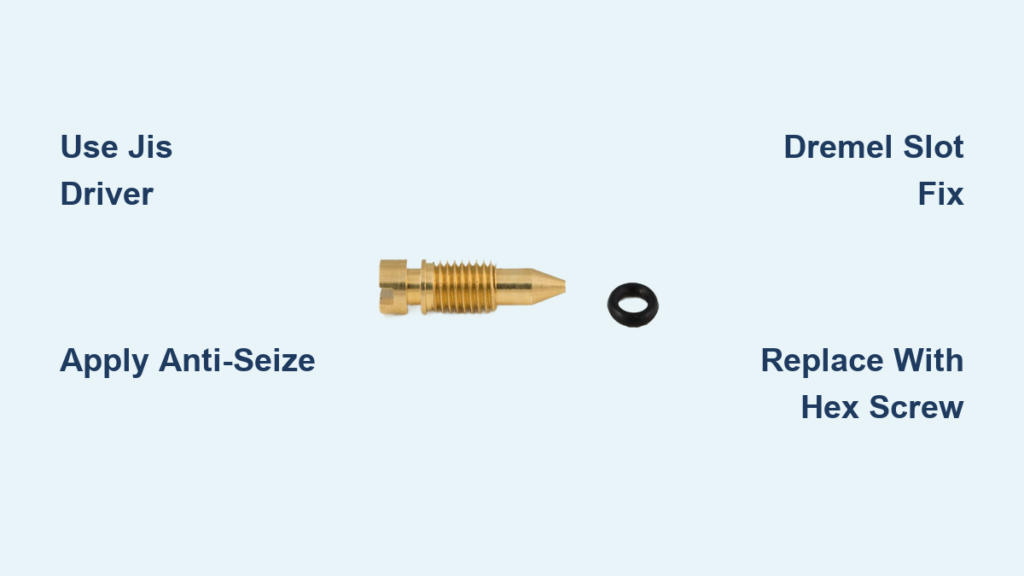

Dremel Slot Method: Permanent Fix for Stripped Screws

When dirt bike fuel bowl drain screw stripping has already occurred, the Dremel slot technique transforms your ruined screw into a reliable flathead interface that accepts common tools.

Cutting Your Emergency Removal Slot

After removing the float bowl for better access, use a Dremel with a thin cut-off wheel to carefully cut a deep groove across the stripped screw head. Work slowly—soft aluminum removes quickly—and stop frequently to check depth. Aim for 80% of the screw head’s thickness to create a robust engagement point without risking damage to the carburetor body. This single modification permanently solves future drainage issues.

Single vs. Dual Slot: Which Works Best?

Most mechanics prefer the single-slot approach for speed and simplicity—it takes just 2-3 minutes and works perfectly with standard flathead screwdrivers. The dual-slot method (cutting perpendicular grooves) offers flexibility to use either flathead or Phillips drivers but requires more precision. For emergency trail repairs, the single-slot method is your fastest path back to riding—it creates a reliable engagement point that won’t strip again.

Screw Extractor Solutions for Stubborn Stripped Screws

When the Dremel method isn’t possible, specialized extractors can rescue even moderately stripped drain screws with the right technique.

Left-Hand Drill Bit Strategy

Start with a small pilot hole using a left-hand drill bit (rotates counterclockwise), then progressively increase bit sizes until you can engage a matching Easy-Out extractor. The left-hand rotation often loosens the screw before extractor contact—this combined approach succeeds where standard methods fail. Apply penetrating oil (Kroil outperforms WD-40) and let it soak overnight for best results on seized screws.

Emergency Torx Conversion Technique

Drill a 2mm hole into the stripped screw head, then step up to a 3mm hole before tapping a Torx T20 screw into the cavity. The Torx screw’s superior grip typically provides enough torque to remove the original fastener. This method works when extractors fail but requires steady hands and proper drill alignment to avoid damaging the carburetor body.

Float Bowl Removal: Your Backup Drainage Plan

When all else fails, removing the entire float bowl accomplishes drainage while providing access for aggressive extraction methods.

Four-Screw Bowl Removal Process

Remove the four JIS screws holding the float bowl to the carburetor body—these often strip too, so use proper technique. The bowl drops straight down, draining fuel instantly while exposing the stripped drain screw for extraction attempts. With the bowl off, you can safely apply heat, impact force, or drilling without risking carburetor damage.

Upgrade Opportunity During Bowl Removal

Replace the four float bowl screws with metric socket head cap screws (allen bolts) to prevent future stripping. This $5 upgrade eliminates 80% of your carburetor screw problems—but be gentle during installation as hardened steel bolts can damage carburetor threads if overtightened. The drain screw remains the weakest point, making proper JIS tools essential for that specific fastener.

Replacement Screw Options That Prevent Future Stripping

After extracting a stripped drain screw, choose replacement options that solve the problem permanently rather than repeating the cycle.

Custom Hex Head Replacement Screws

Machinists like Steve C (stevec5000@yahoo.com) produce hex head drain screws for $10/set that eliminate stripping completely. These custom screws maintain original thread pitch while adding foolproof allen wrench engagement—no more specialized drivers needed. New Zealand machinists also offer socket head versions that perfectly replicate OEM dimensions with superior tool interface.

Stainless Steel Upgrades with Caution

Stainless steel replacements resist corrosion better than brass originals, making future removal easier. However, the increased hardness requires careful torque control—over-tightening can damage carburetor threads since stainless lacks the “torque fuse” protection of softer metals. Apply anti-seize compound to threads during installation for maximum future accessibility.

Emergency Trail Kit for Remote Riding

Prevent being stranded by dirt bike fuel bowl drain screw stripping when water crossings or maintenance emergencies occur far from home.

Must-Carry Extraction Tools

Pack a JIS #2 driver bit in your tool roll if keeping original screws, or the appropriate allen wrench if using hex head replacements. For Dremel-modified screws, include a small flathead screwdriver—this lightweight addition could save your ride. Test your drain screw’s functionality before heading into remote areas to ensure it engages properly.

Pre-Ride Screw Inspection Routine

Before every trail ride, verify your drain screw turns freely with the correct tool. A 10-second check prevents hours of roadside frustration if you need emergency drainage after a water crossing. Apply anti-seize to the threads during your last maintenance session to ensure smooth operation when needed most.

Final Solution Summary: Prevent dirt bike fuel bowl drain screw stripping by using genuine JIS #2 drivers with proper clockwise-first technique and anti-seize compound. When stripping occurs, the Dremel slot method provides the most reliable permanent fix, while float bowl removal offers emergency drainage. Upgrade to custom hex head screws for complete peace of mind—this single modification eliminates the problem forever. Perform quick drain screw checks before every ride to avoid being stranded, and keep the right extraction tools in your trail kit for emergencies. With these solutions, you’ll transform a common frustration into a quick, reliable maintenance step that keeps you riding.