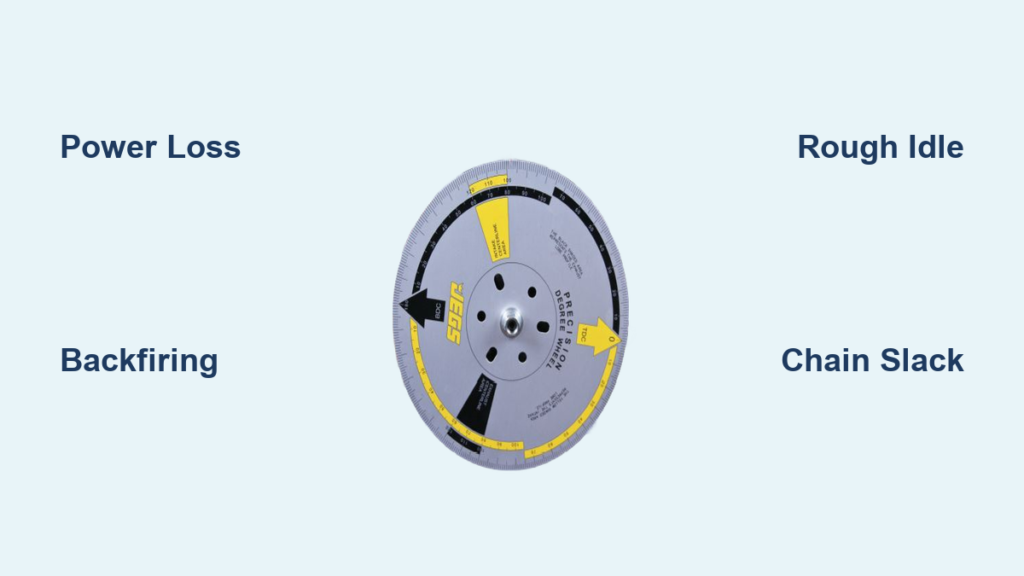

Your dirt bike’s engine suddenly feels sluggish, backfires unexpectedly, and struggles to maintain power on the trail. These frustrating issues might point to one critical problem: your dirt bike timing is off. When the precise synchronization between the crankshaft, camshaft, and valves breaks down, your engine’s performance suffers dramatically. Understanding the specific symptoms of timing issues helps you diagnose problems early before they lead to catastrophic internal damage that requires expensive repairs.

Ignoring timing problems rarely ends well. As the cam chain stretches or the tensioner fails, symptoms worsen until your dirt bike becomes unreliable or completely inoperable. This guide details every symptom you might encounter when timing drifts out of specification, how to distinguish timing issues from other mechanical problems, and what immediate actions you should take to protect your engine.

Why Your Dirt Bike Loses Power with Timing Issues

Immediate Horsepower Reduction Across All Gears

When your dirt bike’s timing slips even slightly, you’ll notice a significant drop in available power. The engine feels weak coming out of corners and struggles to maintain speed on inclines that were previously effortless. This occurs because the valve events no longer align properly with piston position, disrupting the combustion process. Your bike might still reach high RPMs, but the power delivery feels disconnected—like trying to pedal a bicycle with the chain half-off the sprocket. The most noticeable power loss typically hits the mid-range RPMs where most trail riding happens.

Sudden Backfiring During Deceleration

That sharp “pop-pop” sound from your exhaust isn’t just annoying—it’s a red flag for timing problems. Backfiring happens when unburned fuel ignites in the hot exhaust system, usually because the exhaust valve timing has drifted enough to allow fuel-air mixture into the exhaust port at the wrong moment. If you’re hearing these explosive sounds specifically when letting off the throttle, especially after hard riding sessions, your timing has likely shifted significantly. Severe cases might even produce visible flames from the exhaust on deceleration.

Cold Starting Difficulties That Worsen Daily

If your dirt bike has become increasingly difficult to start—particularly when cold—you’re experiencing one of the earliest warning signs of timing issues. What once required one or two kicks now takes multiple attempts as the engine cranks through revolutions without catching. Once it does start, the idle remains unstable, fluctuating wildly or stalling immediately when you release the throttle. This happens because the valve timing no longer creates the proper air-fuel mixture concentration at the optimal moment for combustion, making consistent ignition difficult.

Distinctive Engine Noises That Signal Timing Problems

Metallic Ticking Sounds from the Cylinder Head

Listen carefully to your engine’s upper end while idling. A healthy dirt bike produces a smooth mechanical sound, but when timing drifts, you’ll hear an irregular ticking or clicking noise that seems out of rhythm with normal valve operation. This sound typically intensifies when the engine is cold and might change pitch as the RPM increases. The noise comes from the cam chain slapping against its guide due to excessive slack from stretching or tensioner failure. Unlike normal valve train noise, this ticking often has an uneven pattern that corresponds with chain movement rather than valve operation.

Knocking Under Load That Mimics Bad Fuel

That knocking or pinging sound when climbing hills or accelerating hard could indicate detonation caused by timing issues. While bad fuel often creates this symptom, timing that’s even slightly off can cause premature fuel ignition by creating abnormal pressure spikes in the combustion chamber. The key distinction is that timing-related knocking usually changes based on engine temperature and worsens as the engine heats up, whereas fuel-related knocking tends to be more consistent. If you’ve recently adjusted your timing or performed engine work, this knocking likely points directly to timing misalignment.

RPM-Specific Roughness in the Powerband

Pay attention to when your dirt bike sounds and feels rough. Timing problems often create a “dead spot” in the RPM range where the engine runs noticeably worse than at other speeds. You might find your bike runs smoothly at low RPMs, becomes rough at mid-range, then smooths out again at higher revs. This happens because the valve timing aligns particularly poorly with piston position at certain crank angles. If your powerband used to feel seamless but now has a specific RPM zone where it stutters or hesitates, timing drift should be your primary suspect.

Visible Evidence of Timing Problems

Blue or White Smoke from the Exhaust

While some smoke is normal during cold starts, persistent blue or white smoke indicates serious timing-related issues. Blue smoke suggests burning oil, which can happen when valve guides wear due to improper valve timing causing excessive side loading. White smoke (or steam) points to coolant entering the combustion chamber—often because valves aren’t seating properly due to severe timing misalignment. If you’re seeing either type of smoke consistently, especially after the engine has warmed up, your timing problems have likely progressed to the point of causing internal damage.

Oil Leaks Around the Valve Cover Area

A sudden oil leak from the valve cover gasket might seem like a simple seal failure, but it can actually signal underlying timing problems. When the cam chain becomes excessively loose, it creates abnormal vibration that compromises gasket integrity. If you’ve recently replaced the valve cover gasket only to have the leak return quickly, check your cam chain tension before replacing the gasket again. Oil appearing in unusual places around the cylinder head often correlates with timing components that have worn beyond safe limits.

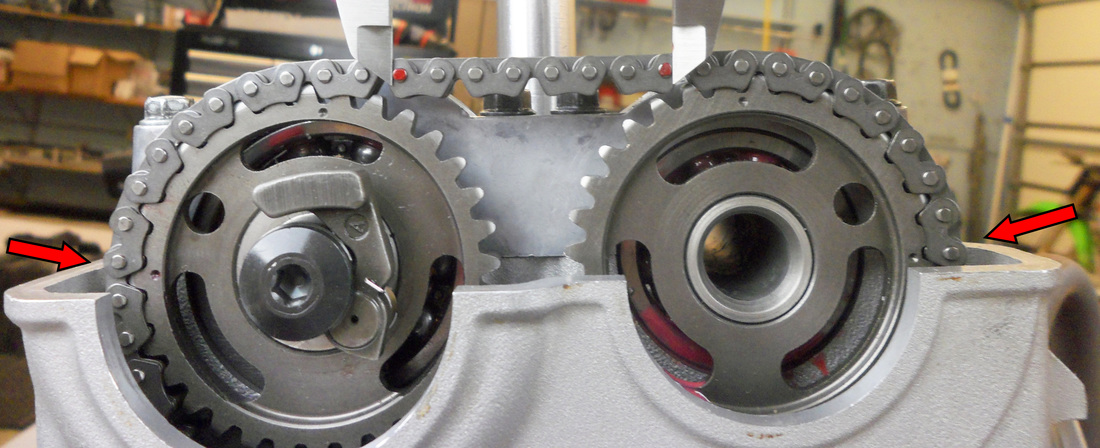

Measurable Cam Chain Slack During Inspection

On many dirt bike models, you can verify timing issues by checking cam chain slack through designated inspection points. With the engine off and cold, locate the chain tensioner inspection port and gently push the chain toward the cam sprocket. Most manufacturers specify less than 10mm of movement—anything beyond this indicates excessive slack. If you can visibly see the chain moving more than a quarter inch when pressed, your timing has likely drifted enough to cause performance issues and requires immediate attention.

Critical Timing Symptoms That Mimic Other Failures

Carburetor-Like Symptoms That Persist After Fuel System Tuning

Hard starting, poor idle, and hesitation often lead riders to blame the carburetor, but these symptoms frequently stem from timing issues instead. The key difference is timing-related problems won’t improve after carburetor adjustments or cleaning. If you’ve recently rebuilt your carburetor or replaced jets but the symptoms remain unchanged—especially if they appeared suddenly after a hard landing or crash—your cam timing has likely shifted. Timing problems create these symptoms abruptly, while carburetor issues typically develop gradually.

Ignition Problems That Change with Engine Position

Backfiring and power loss can suggest faulty spark plugs or CDI units, but timing issues create distinctive patterns. With ignition problems, symptoms remain consistent regardless of engine position, while timing-related issues often change when you rotate the crankshaft manually. If your bike runs better with the front wheel elevated versus on flat ground, or if symptoms vary when you adjust the timing marks slightly, you’re dealing with mechanical timing drift rather than electrical problems.

Immediate Actions When Timing Symptoms Appear

Perform a Basic Compression Check

Before tearing into your engine, verify whether timing issues have caused valve damage with a simple compression test. Remove the spark plug, install a compression gauge, and kick through several full revolutions. Healthy four-stroke dirt bikes typically show 150-180 PSI when warm. Readings below 120 PSI suggest potential valve seating problems related to timing issues. Significant differences between multiple cylinders (more than 15 PSI) indicate uneven timing problems that require immediate attention.

Visually Confirm Timing Marks Alignment

The definitive test for timing problems requires checking the alignment of timing marks. Remove the inspection plug on the crankshaft and the valve cover to access the cam sprockets. Rotate the engine until the piston reaches top dead center (TDC), then verify that the cam sprocket marks align precisely with their reference points. Even a single tooth difference creates noticeable symptoms. If the marks don’t line up perfectly according to your service manual specifications, your timing has slipped and requires correction.

Preventing Costly Timing Failures

Schedule Regular Chain Tension Checks

Don’t wait for symptoms to appear before checking your cam chain. During routine maintenance, verify chain tension according to your manufacturer’s specifications—typically every 10-20 hours of riding. A simple tension check takes minutes but prevents the progressive timing drift that leads to expensive repairs. Mark your maintenance log with the date of each check so you can track tension changes over time and anticipate when replacement becomes necessary.

Replace Chains Before Symptoms Appear

Most dirt bike cam chains require replacement between 100-200 hours of operation, depending on riding conditions. Waiting until you notice symptoms means you’ve already subjected your engine to potentially damaging timing misalignment. When replacing the chain, always inspect the sprockets and tensioner—worn components accelerate chain wear and cause premature timing issues. Quality OEM or premium aftermarket chains provide more consistent tension and longer service life than budget alternatives.

Final Note: Recognizing dirt bike timing off symptoms early prevents minor issues from becoming catastrophic engine failures. The distinctive combination of power loss, unusual noises, and specific RPM-related performance problems creates a diagnostic fingerprint that sets timing issues apart from other mechanical failures. By understanding these symptoms and taking prompt action, you protect your engine from expensive damage while keeping your dirt bike reliable on the trail. Regular chain inspections and timely replacements represent minimal maintenance effort compared to the cost of repairing bent valves or damaged pistons caused by neglected timing problems.