Powder coating your dirt bike rims transforms their appearance while delivering unmatched protection against the relentless punishment of off-road riding. Unlike traditional paint that chips and fades within months, powder coating creates a thick, resilient barrier that withstands rocks, mud, and debris while maintaining its vibrant color through countless trail sessions. Whether you’re restoring a vintage bike, customizing your current ride, or simply tired of peeling factory finishes, mastering how to powder coat dirt bike rims puts professional-grade results within your reach. This comprehensive guide details every critical step from rim removal through final installation, ensuring your wheels emerge with a finish that survives even the toughest terrain.

The true power of powder coating lies in its molecular bonding process, where electrostatically charged powder particles fuse directly with the metal substrate during curing. This creates a single, continuous layer without the weak points found in traditional paint systems. A properly executed powder coat job on your dirt bike rims can easily last a decade or more with minimal maintenance, resisting chips that would expose bare metal to corrosion. Before you begin, understand that success depends almost entirely on meticulous preparation—rushing through cleaning or skipping surface profiling leads to premature failure. Take your time with each stage, and your rims will reward you with years of durable, attractive performance that maintains its showroom quality despite constant exposure to trail hazards.

Why Powder Coating Beats Paint for Dirt Bike Rims

Dirt bike rims endure conditions that destroy conventional paint in weeks. The constant bombardment of rocks, mud, and debris creates micro-chips that expose bare metal to moisture and corrosion. Powder coating eliminates these vulnerabilities by bonding at the molecular level, creating a protective layer that flexes with the rim rather than cracking under impact stress. This resilient finish maintains integrity through temperature extremes, from freezing winter mornings to scorching desert afternoons.

The maintenance advantage becomes immediately apparent after your first muddy ride. Powder coated rims clean up with a simple hose-off, removing caked mud without damaging the finish. Traditional painted rims develop a rough texture that traps dirt in microscopic cracks, making cleaning difficult and accelerating wear. For serious riders, the weight savings matter too—powder coating adds minimal mass compared to multiple layers of paint and clear coat, keeping rotational weight down for quicker acceleration and sharper handling.

Beyond performance, powder coating offers customization possibilities that paint simply cannot match. From sleek matte blacks to vibrant metallics and textured wrinkle finishes, the range of options lets you create a truly unique look. Unlike paint that fades and oxidizes over time, powder coating maintains consistent color density across the entire rim surface, even in direct sunlight. The uniform application eliminates the streaking and orange peel texture common with spray paint, delivering professional results that turn heads at the track.

Essential Equipment for Powder Coating Rims

Gathering the right tools before starting prevents frustrating mid-project interruptions. The powder coating process demands specific equipment, though affordable hobbyist kits have made this professional technique accessible to DIY enthusiasts. Your core investment includes a powder coating gun, powder supply, and curing oven—all available in complete starter packages.

Your powder coating gun should feature adjustable voltage settings (typically 30-100 kV) and powder flow controls. Look for a unit with multiple nozzle tips to handle different rim geometries and powder types. The gun connects to your air compressor, which must deliver clean, dry air at 40-100 PSI—moisture in your air line causes powder clumping and finish defects. A dedicated air dryer or inline moisture filter proves essential for consistent results.

Safety equipment forms a non-negotiable part of your setup. A respirator with P100 filters protects against inhaling fine powder particles during application, while safety glasses prevent eye irritation from stray particles. Nitrile gloves keep oils from your skin off the freshly prepared rims, and a dedicated workshop apron catches overspray. Never skip proper ventilation—powder coating generates airborne particles that require extraction through a dedicated booth or outdoor setup with wind protection.

Preparation supplies include heavy-duty degreasers, sandblasting media (aluminum oxide or garnet), and masking materials for bearing surfaces. A dedicated convection oven—never one used for food—ensures proper curing temperatures. Small rims fit in modified toaster ovens, while larger wheels require dedicated powder curing ovens. Invest in quality wire racks that allow air circulation during curing without leaving contact marks on your finish.

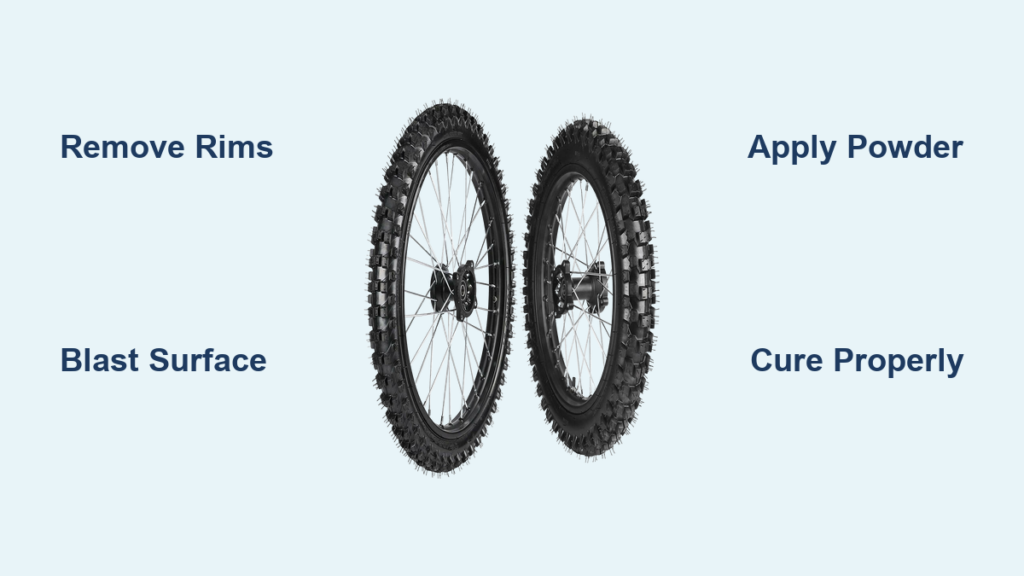

Remove Rims Properly Before Coating

Proper disassembly ensures smooth reinstallation after coating. Begin by securing your bike on a stable stand, then take detailed photos documenting brake line routing, chain tensioner positions, and any unique hardware configurations. Work on one wheel at a time and store components in labeled containers—spacers, washers, and bolts often differ between left and right sides.

For front wheel removal, loosen the axle pinch bolts on both fork legs before removing the axle nut. Support the wheel as you withdraw the axle to prevent damage to brake lines or speed sensors. Carefully remove the brake caliper (hanging it from a zip tie to avoid stressing the brake line) and note the position of any speed sensor rings. Place all hardware in a labeled container corresponding to its location.

Rear wheel removal requires additional steps due to the chain and swingarm. First, loosen the axle adjuster bolts to release chain tension, then remove the axle nut while supporting the wheel. Slide the wheel forward to slacken the chain before lifting it off the sprocket. Pay special attention to the rear brake rotor mounting bolts and any ABS sensor components. Document the position of all spacers between the hub and swingarm—these critical components affect wheel alignment and bearing preload.

With rims removed, inspect wheel bearings and seals for wear. Replace any questionable components now, as accessing them later requires stripping your fresh powder coat. Check brake rotors for excessive wear or warping, and verify tire tread depth—addressing these items during rim removal saves significant time later.

Achieve Perfect Surface Preparation

Surface preparation determines whether your powder coating bonds for years or fails within months. Begin by washing rims with hot, soapy water to remove heavy trail grime, then perform the water break test—properly cleaned metal allows water to sheet off evenly without beading. Any beading indicates residual oils requiring additional degreasing.

Use a dedicated metal prep solution according to manufacturer instructions, applying it with clean rags using unidirectional strokes to prevent recontamination. Pay special attention to spoke holes, valve stem openings, and rim lips where contaminants hide. After degreasing, rinse thoroughly with clean water and dry immediately with compressed air—any standing water causes flash rusting that compromises adhesion.

For existing coatings, chemical strippers or media blasting provide the most effective removal. Chemical strippers work well for small areas but require multiple applications for complete removal. Media blasting creates the ideal surface profile for powder adhesion—use aluminum oxide at 40-60 PSI with consistent, overlapping passes. The goal is a uniform matte finish without deep pitting, especially on aluminum rims. After blasting, blow all crevices clean with compressed air and handle only with clean gloves.

Apply Powder Coat with Professional Technique

With rims properly prepared, begin powder application by grounding your rims directly to clean metal surfaces. Poor grounding causes uneven powder distribution and weak adhesion. Shake your powder vigorously before loading the hopper to prevent settling that causes inconsistent flow.

Hold the gun 6-8 inches from the rim surface, using smooth, overlapping strokes at a consistent speed. Start with light passes to establish an even base layer before building thickness, paying extra attention to edges and spoke holes where coverage tends to be thin. Apply powder in multiple thin coats rather than one heavy application—this prevents orange peel texture and ensures even coverage.

Monitor your film thickness visually; quality powder coating appears uniformly smooth without visible bare spots or heavy buildup. Most applications require 2-3 light passes to achieve proper coverage. If powder begins to fall off during application, your voltage is too low; if it repels itself creating a mottled finish, your voltage is too high.

Cure for Maximum Durability

Curing transforms loose powder into a hard, resilient finish through precise heat application. Preheat your oven to the manufacturer’s specified temperature (typically 350-400°F) and allow it to stabilize before introducing coated rims. Place rims on wire racks that allow 360-degree air circulation—direct contact with oven surfaces creates flat spots in your finish.

Curing time begins when the rim metal reaches target temperature, not when placed in the oven. Use an infrared thermometer to verify rim surface temperature before starting your timer—most powders require 10-15 minutes at full temperature. Under-curing leaves the finish soft and vulnerable, while over-curing causes brittleness and color shifts.

After curing, allow rims to cool completely before handling. Rapid cooling causes thermal shock that creates micro-cracks in the finish. Never rush this stage—let rims cool naturally in a clean, dust-free environment.

Reinstall and Maintain Your Powder Coated Rims

Before reinstalling, inspect your finish for any curing defects. Small imperfections can sometimes be touched up with matching powder and a heat gun, but significant issues require stripping and recoating. Follow your disassembly documentation to reinstall components in their proper positions, tightening all fasteners to manufacturer specifications.

Apply anti-seize compound to axle threads to prevent galling and make future removal easier. During tire mounting, use generous amounts of tire mounting lubricant to prevent the tire beads from dragging against the rim finish. Avoid metal tools that can scratch the coating—use plastic tire irons exclusively.

Maintain your powder coated rims with regular cleaning using mild soap and water. Avoid harsh chemical cleaners that can degrade the finish over time. Inspect rims after each ride for chips or scratches, touching up any damage immediately with matching powder to prevent corrosion from starting.

Powder coated dirt bike rims transform your machine’s appearance while delivering unmatched protection against trail abuse. The process demands patience and attention to detail, particularly during surface preparation, but the results justify the effort—your rims emerge with a finish that resists chips, scratches, and corrosion while maintaining vibrant color through years of hard riding. With proper maintenance and occasional touch-ups, your powder coated rims will serve your riding adventures for the life of your bike, delivering both aesthetic appeal and practical durability that far exceeds conventional paint in every meaningful measure.