There’s nothing more frustrating than preparing for a ride only to discover your bike tire won’t hold air because the valve keeps moving in and out. If you’ve ever pushed down on your bike tire valve while pumping and watched your tire deflate instead of inflate, you know exactly how maddening this problem can be. A valve that won’t stay in position transforms what should be a quick inflation into a full maintenance headache. The good news is that learning how to fix a bike tire valve is simpler than most cyclists realize, often requiring nothing more than basic tools and about fifteen minutes of your time.

This comprehensive guide walks you through every aspect of diagnosing and resolving valve issues, from identifying your specific valve type to executing both temporary and permanent solutions. Whether you ride a road bike with narrow Presta valves or a mountain bike equipped with Schrader valves, you’ll find actionable steps tailored to your setup. By the end of this article, you’ll understand exactly what’s causing your valve problem and how to resolve it—whether that means tightening a simple lock nut, replacing a worn seal, or taking more advanced measures to ensure your tires stay properly inflated.

Identify Your Valve Type Before Repairs

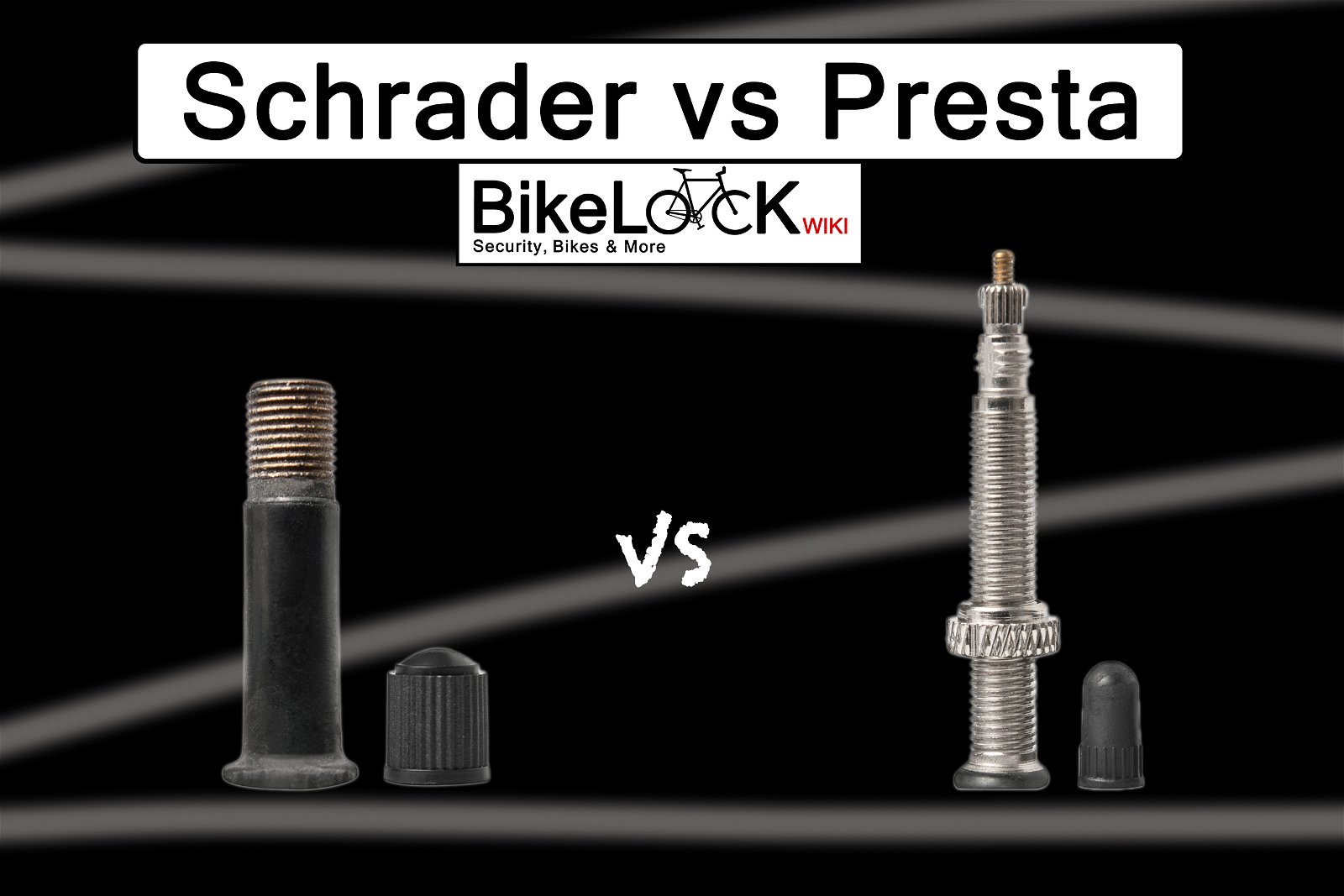

Before you can effectively fix a bike tire valve, you need to know exactly what type of valve you’re working with. Using the wrong technique on the wrong valve type won’t just fail to solve your problem—it could potentially cause additional damage.

Presta valves are the slender valves found on most road bikes and performance-oriented mountain bikes. They’re easily recognizable by their narrow diameter (about 6mm) and threaded metal shaft. At the top of a Presta valve, you’ll notice a small lock nut that must be loosened before inflation and tightened afterward. These valves are designed specifically for high-pressure applications, which is why bicycle manufacturers favor them for road cycling where tire pressures often exceed 100 PSI.

Schrader valves are the wider valves (about 8mm in diameter) that closely resemble those found on automobile tires. They feature a spring-loaded internal pin that controls airflow. When you press on a Schrader valve core, you’re compressing that internal spring to allow air to escape. This same mechanism explains why these valves sometimes deflate mysteriously when something presses against the valve pin.

⚠️ Important Warning: If pushing your valve stem inward caused immediate deflation, you might be dealing with a tubeless tire setup. In tubeless configurations, the valve isn’t designed to be pushed in at all, and disturbing it can break the airtight seal between the valve and the rim. Proceed with caution and consider whether your setup requires special handling.

Temporary Fix: Inflate Without Removing the Valve

When your tire is nearly flat and you need air immediately, there’s a clever workaround that lets you inflate without first fully fixing the underlying valve problem.

Begin by gripping the valve stem firmly right where it exits the tire—this prevents movement while you work. With your other hand, attach your pump head to the valve as securely as possible. Pump slowly and deliberately. As air enters the tire and internal pressure builds, that pressure actually pushes the valve mechanism outward, helping it reseat properly.

Continue pumping until your tire reaches a minimum pressure of about 20 to 30 PSI. At this point, most valves will stay in position without requiring you to hold them. The air pressure inside the tire creates a natural seal that holds everything in place. For Presta valve owners, this is the perfect moment to tighten down the lock nut at the top of the valve stem.

✅ Pro Tip: If you’re using a floor pump with a pressure gauge, pay attention to how the gauge behaves as you pump. If pressure rises normally once you get past that initial low point, your valve is likely functioning correctly now. If pressure refuses to build or immediately drops when you stop pumping, you have a more serious leak that requires additional diagnosis.

Fix Presta Valve Looseness Permanently

Presta valves suffer from one primary problem more than any other: the lock nut at the top works loose over time, allowing the entire valve to move up and down within the rim hole. Fixing this issue requires only a few minutes and possibly a replacement part.

Start by fully deflating your tire so you can work without pressure fighting you. Once the tire is flat, locate the lock nut at the top of your Presta valve. Unscrew the lock nut completely and set it aside temporarily.

With the nut removed, check the condition of the valve stem itself. Is it cracked, bent, or corroded? Any visible damage means you should replace the entire valve rather than trying to salvage a compromised component. If the stem looks intact, examine the rim hole where the valve passes through. Make sure no debris is lodged in or around the hole that might prevent a proper seal.

Now, reinsert the valve through the rim from inside the tire. Push it through until about 2-3mm of the valve protrudes past the rim’s outer edge—this positioning is optimal for inflation and stability. Hold the valve in this position while you thread the lock nut back on from the outside. Hand-tighten the nut firmly, then give it one-quarter turn with pliers to ensure it won’t work loose again during normal use.

⚠️ Critical Mistake to Avoid: Over-tightening the lock nut can damage the valve stem or rim. The nut should be snug but not so tight that it deforms the valve or makes removal difficult later.

Fix Schrader Valve Problems Completely

Schrader valves are more robust than Presta valves, but they have their own failure modes that require different solutions. The most common Schrader valve problem involves the internal rubber seal that sits just below the valve pin. Over time, this seal can crack, dry out, or become deformed, allowing air to escape past the pin.

To diagnose a Schrader valve issue, remove the valve core using a specialized removal tool—these come with most bike repair kits. Once the core is out, inspect the rubber seal at the bottom of the valve stem. It should be supple and intact, with no visible cracks, tears, or hardening. If the seal shows any signs of wear, replacement is necessary.

Before installing a new core, take the opportunity to clean out any debris that might have accumulated inside the valve stem. A small blast of compressed air or a quick rinse with isopropyl alcohol followed by thorough drying works well. Once everything is clean and dry, screw in your new valve core hand-tight first, then give it a final quarter-turn with your core removal tool to ensure it’s secure.

Replace Worn Valve Cores and Stems

When your diagnosis reveals damaged internal components rather than simple looseness, core or stem replacement becomes necessary.

Valve core replacement is the easiest repair to perform. Insert the core removal tool into the core, turn counterclockwise to unscrew the old core, then dispose of it properly. Take your new core, screw it in clockwise using the same tool, and tighten until snug. Don’t overtighten, as this can strip the threads in the stem.

⚠️ Note: Before removing a valve core from a tubeless tire setup, check whether your tire sealant is fresh. Removing the core releases pressure and can allow sealant to ooze out. Have a rag ready to catch any mess, and plan to check your sealant level afterward.

Full valve stem replacement is required when the stem itself is cracked, the base is corroded, or you’ve tried everything else without success. This repair is more involved because you need to remove the tire from the rim to access the valve stem from the inside. Start by deflating the tire completely, then break one bead loose from the rim using tire levers. Work your way around the tire until you can pull the tire away from the rim near the valve hole.

Prevent Future Valve Problems

The best repair is the one you never have to make. By adopting a few simple habits and performing regular maintenance, you can dramatically reduce your chances of encountering valve problems.

Always use the correct pump head for your valve type. Modern pumps often feature reversible heads that accommodate both Presta and Schrader valves, but you must manually select the correct side before attaching. Forcing a Schrader pump head onto a Presta valve, or vice versa, can damage the valve threads.

Keep your valve stems clean and protected when not in use. Dust, grit, and road grime can work their way into the valve mechanism and cause premature wear. After riding in wet or muddy conditions, wipe down your valve stems and ensure the caps are securely in place.

When inflating any tire, never push down on the valve stem to test or release air unless you deliberately intend to deflate. This simple mistake accounts for a shocking number of valve problems. If you need to check pressure, use a separate pressure gauge rather than pressing on the valve.

Finally, check your valve security every few weeks, especially if you frequently inflate to high pressures or ride on rough terrain. A quick hand-tightness check on Presta lock nuts takes seconds and catches problems before they develop into full-blown failures.

Final Thoughts on Valve Maintenance

Learning how to fix a bike tire valve transforms you from a cyclist who dreads flat tires into someone who handles them confidently. Most valve problems take less time to diagnose than to read about, and the satisfaction of completing the repair yourself makes every future ride more enjoyable.

Remember that recurring valve issues often signal larger maintenance needs. A valve that keeps working loose might indicate worn rim holes, excessive vibration from an improperly adjusted wheel, or simply age-related wear. Use these minor repairs as opportunities to inspect your entire wheel system and address underlying causes. Your bike will thank you with thousands of miles of reliable service.

With the knowledge you’ve gained about how to fix a bike tire valve, you’re now equipped to handle one of cycling’s most common frustrations. Save this guide for your next maintenance session, and you’ll find that what once seemed like a major setback is actually a minor inconvenience that takes just minutes to resolve. Keep riding!